- MTG/C blast furnace gas burner

- MTG/D automatic large split type gas burner series

- MTG/F generator gas burner

- MTG/J coke oven gas burner

- MTGL automatic integrated oil and gas burner serie

- MTG/N split high temperature gas burner

- MTG automatic one - piece gas burner series

- MTL/B automatic large split type light oil burner

- MTL automatic one - piece fuel burner series

- Low NOx burner

MTG/F furnace gas burner

Product overview:

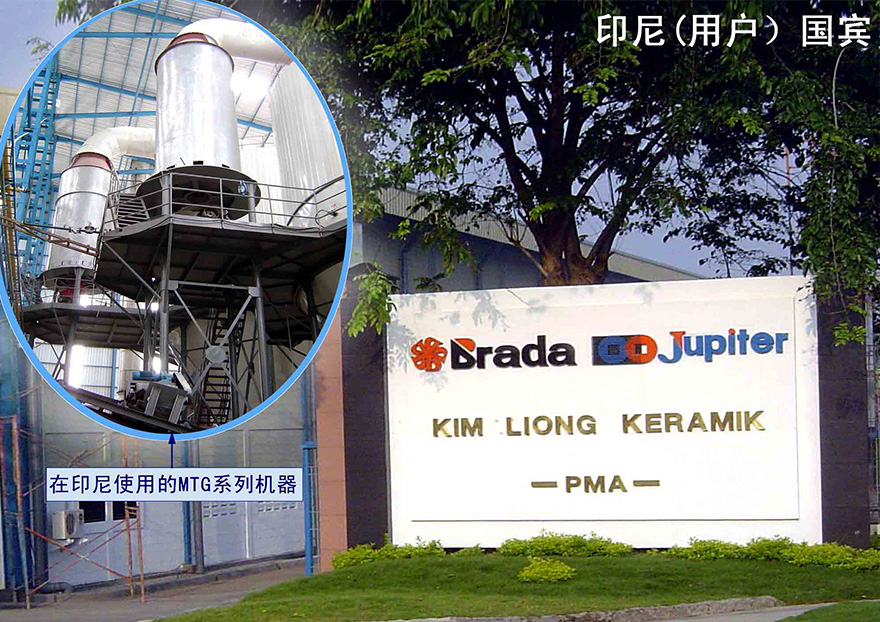

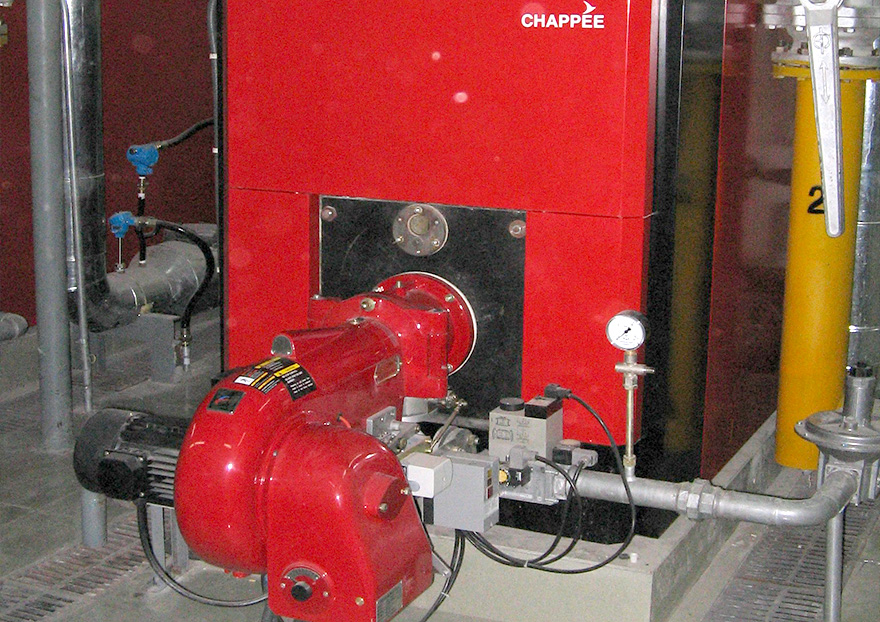

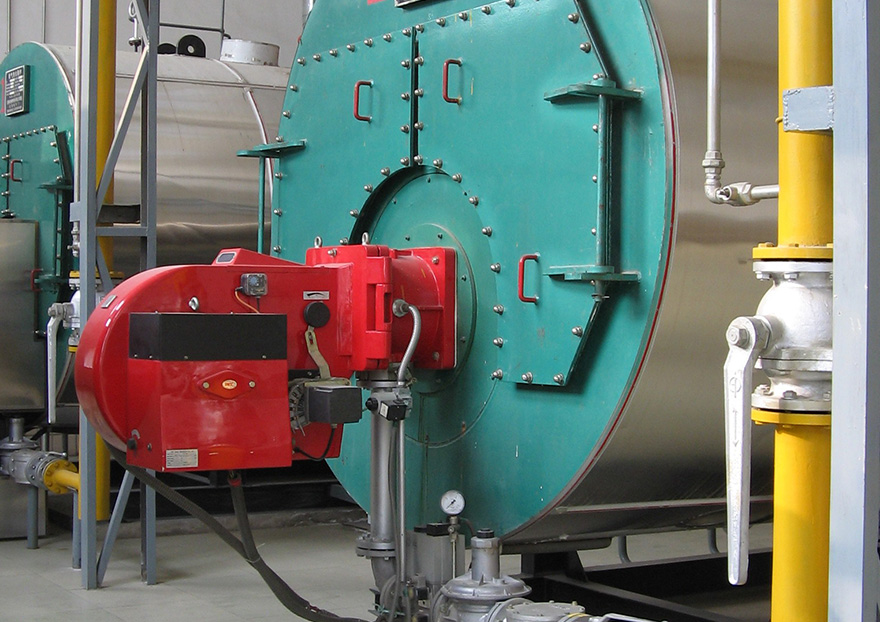

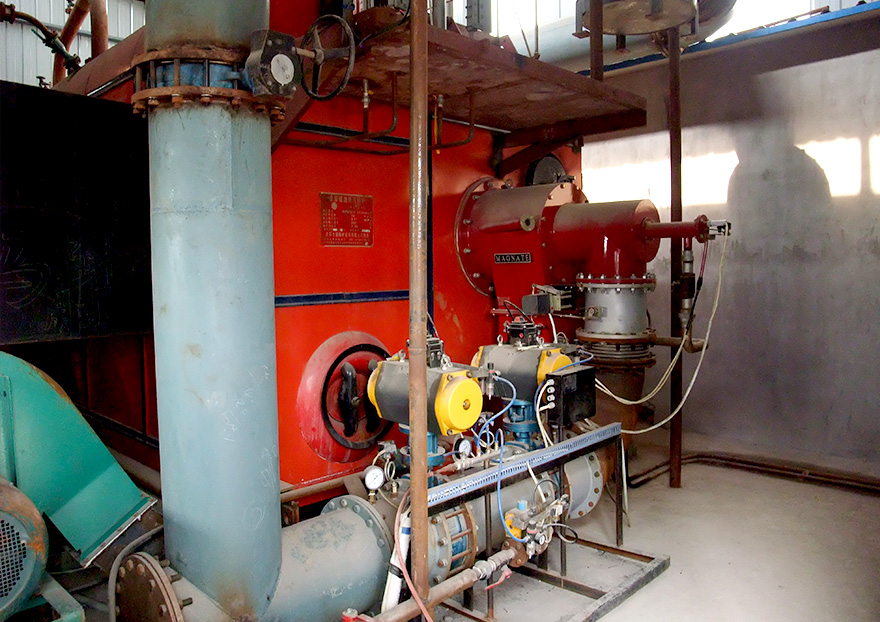

MAGNATEMTG/FType generator gas burner used in today's world of advanced combustion technology, with reference to international and domestic standards, in order to meet the producer gas, flammable chemical tail gas and other types of combustible gas and mechanical and electrical integration of the design and manufacture of automatic split type generator gas burner, widely used in steam boiler, hot water boiler, heat conduction oil furnace, direct-fired lithium bromide air conditioning unit, air heating furnace and other industrial kiln, etc.

Characteristics of furnace gas: flammable and explosive, gas itself has a certain toxicity, industrial production of gas quality and pressure fluctuations, furnace gas components are not fixed, with the fuel——Different types of coal and different operating conditions fluctuate within a certain range.

Our company adopts high calorific value fuel (natural gas, liquefied petroleum gas or light oil) to set a long open flame in the design, so as to ensure the stability and safety of flame in case of fluctuation.

Adaptive fuel:1100kcal/Nm3≤Gas calorific value<2200kcal/Nm3。

Performance characteristics:

● Fully automatic operation, suitable for a wide range of power

● Gas pressure protection, air pressure protection

● Prepurge the furnace

● Safe flame monitoring system

● When the burner stops, the damper automatically closes

● Dual gas shut-off valve, gas valve group automatic leak detection

● SiemensLMVElectronic proportional control system(optional)

● The flue gas oxygen quantity feedback regulation, ADAPTS the fuel gas which the calorific value changes in certain scope, realizes the energy conservation(optional)

Technical parameters:

|

Model |

Capacity |

|

Rated power of fan |

With the boiler |

|

|

KW |

104kcal/h |

KW |

T/h |

||

|

MTG70/F |

872 |

75 |

(Slide two-stage or proportional control) |

2.2 |

1 |

|

MTG105/F |

1300 |

112 |

4 |

1.5 |

|

|

MTG140/F |

1750 |

150 |

4 |

2 |

|

|

MTG280-1/F |

2615 |

225 |

7.5 |

3 |

|

|

MTG280/F |

3500 |

300 |

7.5 |

4 |

|

|

MTG350/F |

4260 |

366 |

11 |

5 |

|

|

MTG420/F |

5250 |

452 |

15 |

6 |

|

|

MTG560/F |

7000 |

602 |

15 |

8 |

|

|

MTG700/F |

8720 |

750 |

30 |

10 |

|

|

MTG1050/F |

13000 |

1118 |

37 |

15 |

|

|

MTG1400/F |

17400 |

1496 |

55 |

20 |

|

*The fan is modified according to the back pressure and altitude of the equipment.

*The combustion chamber back pressure shall not be greater than2000Pa。

Installation dimensions:

|

Model |

Size(mm) |

|||||||||||

|

D1 |

D2 |

D3 |

D4 |

L1 |

L2 |

L3 |

L4 |

H1 |

H2 |

n×d |

A×B |

|

|

MTG70/F |

φ400 |

φ330 |

φ266 |

DN125 |

223 |

1220 |

265 |

320 |

522 |

375 |

4×φ22 |

200×150 |

|

MTG105/F |

φ450 |

φ350 |

φ308 |

DN150 |

280 |

1350 |

240 |

403 |

563 |

400 |

8×φ18 |

240×240 |

|

MTG140/F |

φ450 |

φ350 |

φ308 |

DN150 |

280 |

1350 |

240 |

403 |

563 |

400 |

8×φ18 |

240×240 |

|

MTG280-1/F |

φ450 |

φ390 |

φ362 |

DN200 |

280 |

1415 |

250 |

443 |

563 |

368 |

8×φ18 |

260×240 |

|

MTG280/F |

φ450 |

φ390 |

φ362 |

DN200 |

280 |

1415 |

250 |

443 |

563 |

368 |

8×φ18 |

260×240 |

|

MTG350/F |

φ570 |

φ515 |

φ470 |

DN250 |

320 |

1775 |

440 |

490 |

690 |

540 |

8×φ18 |

400×350 |

|

MTG420/F |

φ616 |

φ556 |

φ535 |

DN300 |

320 |

1815 |

440 |

490 |

690 |

540 |

8×φ18 |

400×350 |

|

MTG560/F |

φ740 |

φ665 |

φ615 |

DN350 |

450 |

1980 |

380 |

583 |

757 |

640 |

12×φ22 |

400×400 |

|

MTG700/F |

φ740 |

φ710 |

φ660 |

DN350 |

450 |

1980 |

380 |

583 |

757 |

640 |

12×φ22 |

400×400 |

|

MTG1050/F |

φ1060 |

φ850 |

φ800 |

DN400 |

400 |

2250 |

514 |

770 |

1007 |

848 |

16×φ22 |

760×565 |

|

MTG1400/F |

φ1060 |

φ970 |

φ920 |

DN400 |

400 |

2250 |

515 |

770 |

950 |

820 |

16×φ22 |

760×565 |

Note:D2For boiler front plate hole size.