- MTG/C blast furnace gas burner

- MTG/D automatic large split type gas burner series

- MTG/F generator gas burner

- MTG/J coke oven gas burner

- MTGL automatic integrated oil and gas burner serie

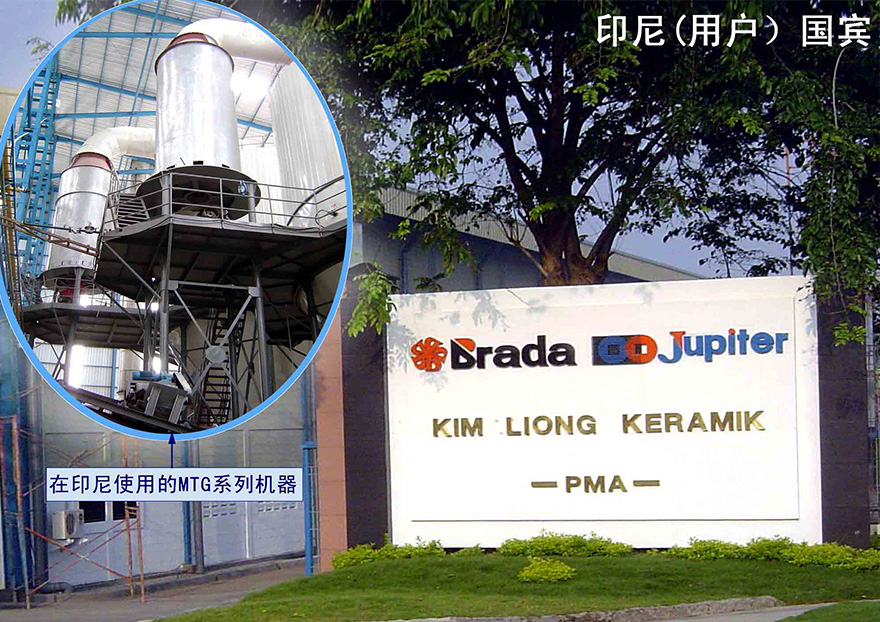

- MTG/N split high temperature gas burner

- MTG automatic one - piece gas burner series

- MTL/B automatic large split type light oil burner

- MTL automatic one - piece fuel burner series

- Low NOx burner

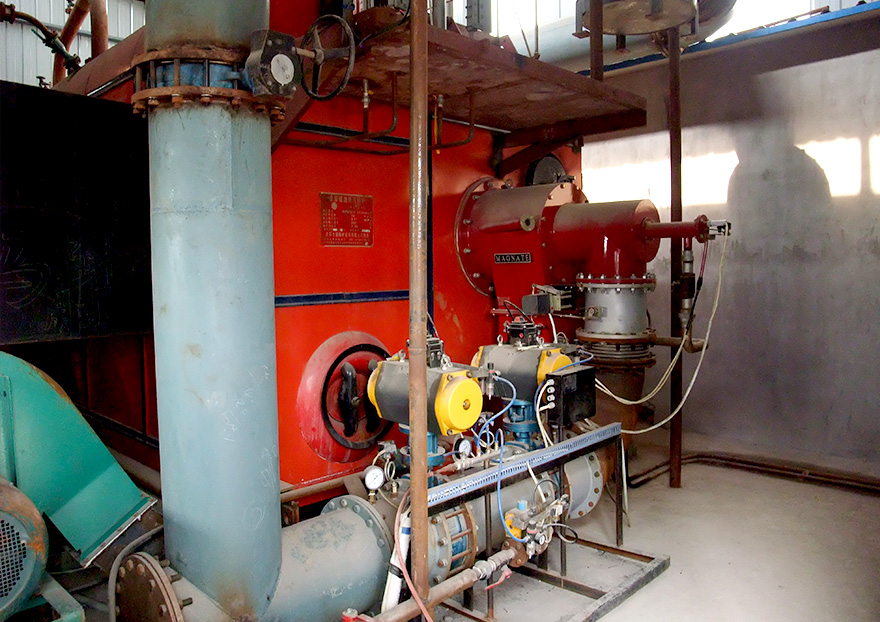

MTG-N

Product overview:

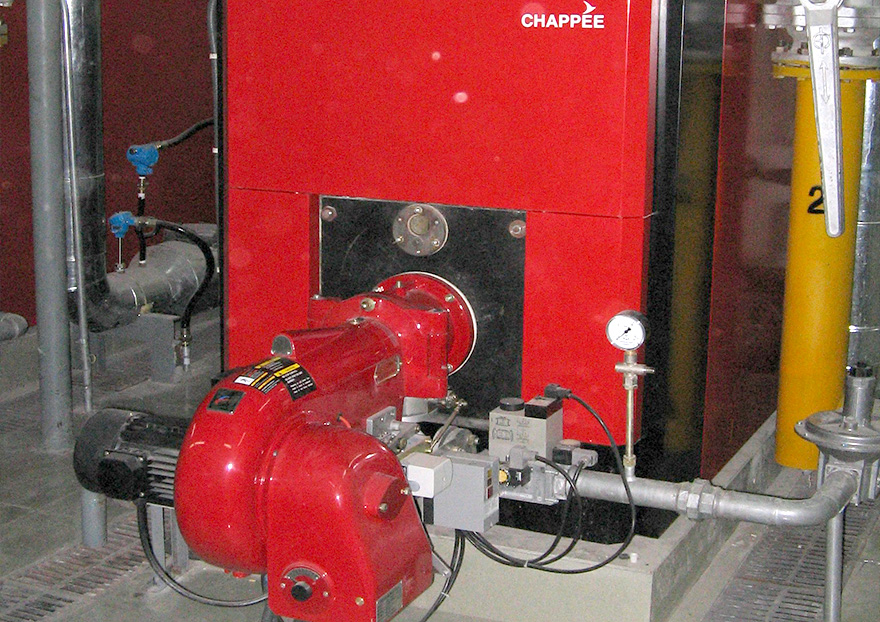

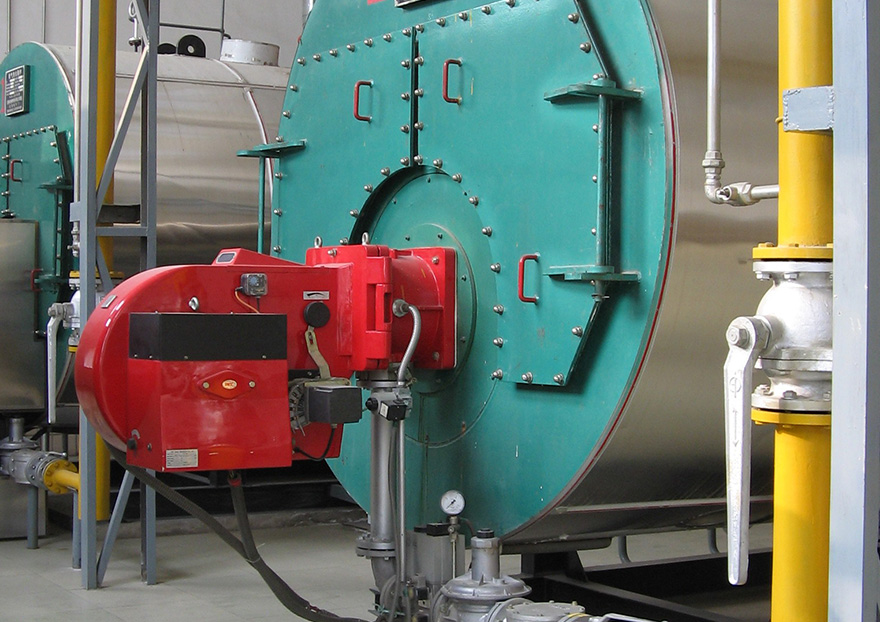

MTG/NType v high temperature resistant burner adopts the world's advanced combustion technology, with referenceEN676It is widely used in steam boiler, hot water boiler, heat conduction oil furnace, direct-fired lithium bromide refrigeration unit, air heating furnace and other industrial kilns.

MTG/NType v high temperature resistant burner can withstand250℃Combustion air at the following temperatures,It has the characteristics of environmental protection and energy saving.

MTG/NType v high temperature resistant burner gas valve set, program controller, damper actuator and so on all adopt the international famous brand, to ensure excellent burner performance, safety performance and reliable operation.

MTG/NType v high temperature resistant burner is light and easy to install.

MTG/NType v high temperature resistant burner has low running noise and meets the requirement of environmental protection.

MTG/NType v high temperature burners are suitable for different types of gas.

MTG/NType v high temperature resistant burner adopts split structure, the selection and installation of fan is flexible, can adapt to the needs of users. Suitable for different back pressure heating device.

Adaptive fuel: calorific value of gas>4500kcal/Nm3。

The performance characteristics of:

Wide applicable power range

Fully automatic operation

Gas leakage automatic detection, double solenoid valve set

Gas pressure protection, air pressure protection

Pre - purge and post - purge the furnace

Safe flame monitoring system

When the burner stops, the damper automatically closes

Divided into fuelMTG/N、fuelMTL/NAnd dual fuel oil and gasMTGL/NThree series.

The dual fuel can switch freely between gas and fuel.

Easy installation, commissioning and maintenance

Technical parameters:

|

Model |

MTX35/N |

MTX 70/N |

MTX 105/N |

MTX 140/N |

MTX 280-1/N |

MTX 280/N |

MTX 350/N |

MTX 420/N |

MTX 560/N |

MTX 700/N |

|

Gas species |

Natural gas |

|||||||||

|

Heat output kw |

100~ 640 |

175~ 940 |

300~ 1750 |

400~ 2250 |

500~ 3600 |

500~ 4100 |

900~ 4750 |

600~ 5400 |

1000~ 8200 |

1000~ 10500 |

|

The power supply |

380V 3/N/PE 50Hz |

|||||||||

|

blower |

The fan is modified according to the back pressure and altitude of the equipment |

|||||||||

|

The control mode |

Sliding two - stage or proportional adjustment type |

|||||||||

|

Program controller model number |

LFL1.322&LGK16 |

|||||||||

★ MTX“X”Fuel gasMTG、fuelMTL、Hydrocarbon bifuelMTGL。

★ Thermal output refers to the output power of the burner at room temperature.

Installation size:

|

Size(mm) |

MTG 35/N |

MTG 70/N |

MTG 105/N |

MTG 140/N |

MTG 280-1/N |

MTG 280/N |

MTG 350/N |

MTG 420/N |

MTG 560/N |

MTG 700/N |

|

L1 |

166 |

210 |

243 |

243 |

242 |

242 |

270 |

385 |

430 |

430 |

|

L2 |

98 |

110 |

120 |

120 |

130 |

130 |

150 |

158 |

185 |

185 |

|

L3 |

310 |

330 |

360 |

360 |

400 |

400 |

410 |

400 |

470 |

470 |

|

L4 |

325 |

440 |

465 |

465 |

530 |

530 |

530 |

600 |

630 |

630 |

|

L5 |

480 |

575 |

640 |

640 |

805 |

805 |

710 |

652 |

1024 |

1024 |

|

H1 |

174 |

192 |

217 |

217 |

260 |

260 |

290 |

290 |

317 |

317 |

|

H2 |

310 |

392 |

440 |

440 |

521 |

521 |

475 |

525 |

651 |

651 |

|

D1 |

φ160 |

φ200 |

φ250 |

φ265 |

φ327 |

φ327 |

φ380 |

φ350 |

φ480 |

φ480 |

|

D2 |

φ190 |

φ240 |

φ290 |

φ300 |

φ360 |

φ360 |

φ420 |

φ390 |

φ520 |

φ520 |

|

D3 |

φ170 |

φ210 |

φ270 |

φ275 |

φ340 |

φ340 |

φ390 |

φ390 |

φ500 |

φ500 |

|

m-D4 |

7-M12 |

7-M12 |

7-M12 |

7-M12 |

7-M12 |

7-M12 |

7-M12 |

7-M16 |

7-M16 |

7-M16 |

|

n-D5 |

8-φ12 |

8-φ14 |

8-φ14 |

8-φ14 |

12-φ14 |

12-φ14 |

12-φ14 |

16-φ14 |

16-φ14 |

16-φ14 |

|

A1 |

295 |

320 |

370 |

370 |

460 |

460 |

485 |

538 |

622 |

622 |

|

A2 |

255 |

280 |

330 |

330 |

410 |

410 |

435 |

486 |

572 |

572 |

|

A3 |

290 |

324 |

374 |

374 |

448 |

448 |

473 |

508 |

598 |

598 |

|

A4 |

250 |

284 |

334 |

334 |

408 |

408 |

423 |

468 |

558 |

558 |

|

A5 |

190 |

224 |

274 |

274 |

348 |

348 |

373 |

408 |

498 |

498 |

User notes:

▲ The user shall provide the gas type and relevant data to the supplier before ordering.

▲ The selected fan should be balanced to meet the system requirements.

▲ Installation and commissioning personnel must undergo professional training.

▲ Must pay attention to the burner installation and related equipment in accordance with the relevant safety specifications.

▲ Due to the continuous development of technology, the data listed in this information are subject to change without notice.

Quality assurance and after-sales service:

▲ Our products within a year to implement three guarantees, life - long maintenance.

▲ Our product debugging, service to ensure that the first time to reach the user.

▲ Our products will have professional and technical personnel to implement the whole tracking service users.