- MTG/C blast furnace gas burner

- MTG/D automatic large split type gas burner series

- MTG/F generator gas burner

- MTG/J coke oven gas burner

- MTGL automatic integrated oil and gas burner serie

- MTG/N split high temperature gas burner

- MTG automatic one - piece gas burner series

- MTL/B automatic large split type light oil burner

- MTL automatic one - piece fuel burner series

- Low NOx burner

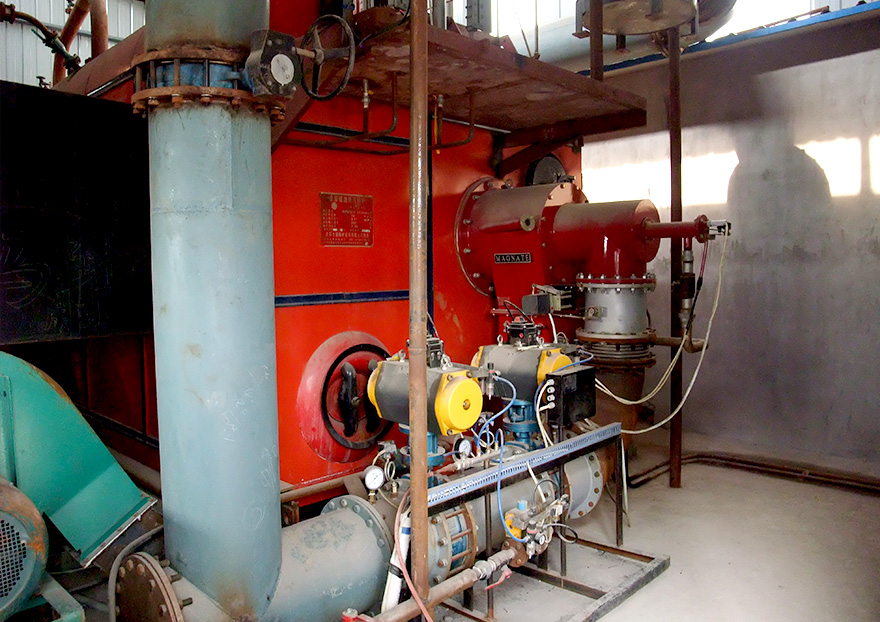

Manette MTG/C series bf gas burner

Product overview:

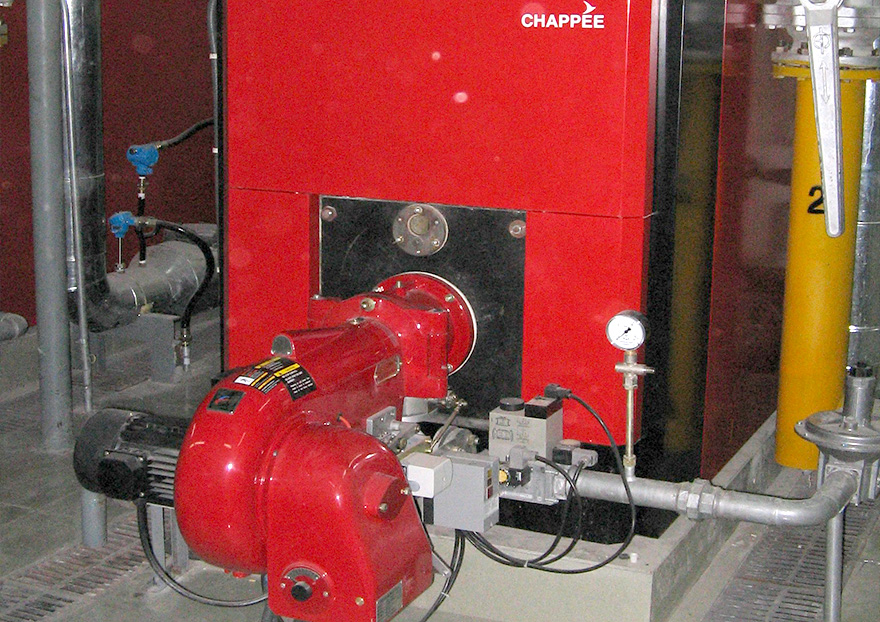

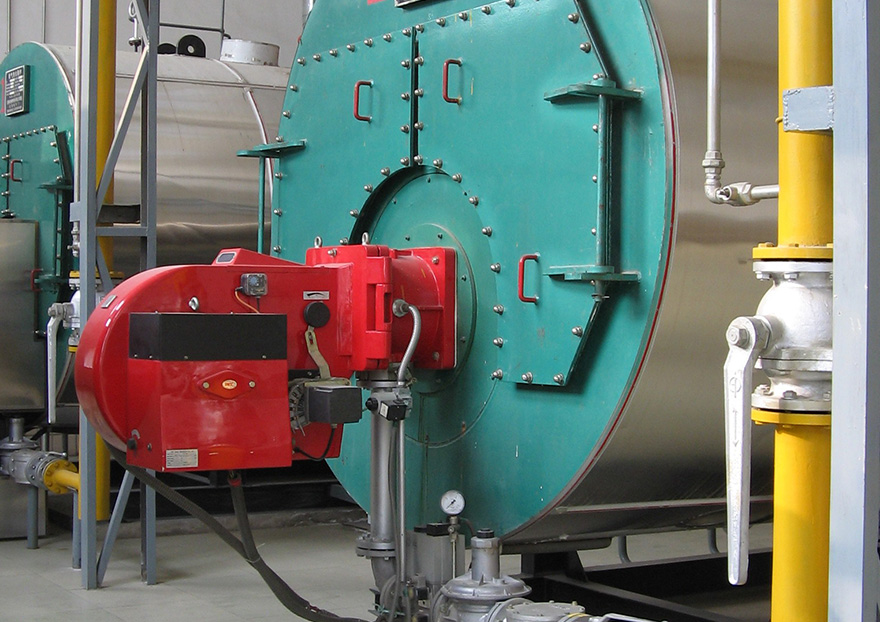

MTG/CSeries bf gas burners are designed and manufactured according to the combustion characteristics of bf gas and the relevant international and domestic standards. They can be widely used in steam boilers, hot water boilers and other industrial furnaces.

MTG/CSeries of bf gas burners gas valve sets, programmed controllers, damper actuators and other famous brands are used to ensure excellent burner performance, safety performance and reliable operation.

Characteristics of blast furnace gas burner:

In view of the characteristics of low calorific value, difficult ignition, easy deignition and slow reaction speed of blast furnace gas, the design and manufacture of the blast furnace gas burner adopts the three-stage combustion mode, namely, the three-stage combustion of high-calorific value fuel is ignited first(Such as natural gas, liquefied gas)And as a part of the constant open fire ignition gas(Auxiliary gas)The main coal gas is ignited after stable combustion. The inner part of the burner is arranged with a heat-resistant stable combustion chamber. The gas and air are mixed in the circular slit with swirl vane and then spurted out for combustion, ensuring combustion stability and sufficiency.

Adaptive fuel:600kcal/Nm3≤Gas calorific value<1100kcal/Nm3。

According to the requirements of the corresponding parts of the transformation can be adapted250℃Below high temperature combustion air.

Technical parameters:

|

Model |

Maximum output |

Regulation mode |

Blower power |

With the boiler |

|

|

KW |

104kcal/h |

KW |

T/h |

||

|

MTG70/C |

850 |

73 |

Slide two-stage or proportional control |

2.2 |

1 |

|

MTG140/C |

1700 |

146 |

4 |

2 |

|

|

MTG280-1/C |

2550 |

219 |

5.5 |

3 |

|

|

MTG280/C |

3400 |

292 |

7.5 |

4 |

|

|

MTG420/C |

5100 |

439 |

11 |

6 |

|

|

MTG560/C |

6800 |

585 |

15 |

8 |

|

|

MTG700/C |

8500 |

731 |

22 |

10 |

|

|

MTG1050/C |

12750 |

1096 |

30 |

15 |

|

|

MTG1400/C |

17000 |

1462 |

45 |

20 |

|

|

MTG1750/C |

21250 |

1827 |

55 |

25 |

|

Note:

The gas consumption is the calorific value of blast furnace gas800kcal/Nm3Calculation.

In the elevation500mAbove, must be recalculated for wind and fan power.

The performance characteristics of:

l Fully automatic operation, suitable for a wide range of power

l Gas pressure level protection

l Air pressure protection

l Dual gas shut-off valve, gas valve group automatic leak detection

l Safe flame monitoring and flameout protection control

l Automatic prepurge and postpurge

l The damper closes automatically when the burner stops

l SiemensLMVElectronic proportional control system(optional)

l The flue gas oxygen quantity feedback regulation, ADAPTS the fuel gas which the calorific value changes in certain scope, realizes the energy conservation(optional)

Installation dimensions

Ordering instructions:

▲ The user shall provide the gas data to the supplier before ordering.

▲ Installation and commissioning personnel must undergo professional training.

▲ Must pay attention to the burner installation and related equipment in accordance with the relevant safety specifications.

▲ Due to the continuous development of technology, the data listed in this information are subject to change without notice.

Quality assurance and after-sales service:

▲ Our products within a year to implement three guarantees, life - long maintenance.

▲ Our product debugging, service to ensure that the first time to reach the user.

▲ Our products will have professional and technical personnel to implement the whole tracking service users.

|

Model |

Size(mm) |

||||||||||||||||||||||||

|

L |

L1 |

L2 |

L3 |

L4 |

D1 |

D2 |

D3 |

D4 |

H1 |

H2 |

H3 |

d1 |

d2 |

n |

d |

P |

P1 |

P2 |

Q |

Q1 |

Q2 |

S1 |

S2 |

R |

|

|

MTG70/C |

1650 |

420 |

470 |

200 |

250 |

400 |

430 |

530 |

600 |

750 |

505 |

100 |

50 |

150 |

12 |

18 |

310 |

210 |

260 |

260 |

160 |

210 |

65 |

70 |

Φ14 |

|

MTG140/C |

1650 |

420 |

470 |

200 |

250 |

520 |

550 |

650 |

700 |

750 |

505 |

100 |

50 |

200 |

12 |

18 |

340 |

240 |

290 |

340 |

240 |

290 |

95 |

95 |

Φ14 |

|

MTG280/C |

1800 |

635 |

540 |

260 |

260 |

750 |

780 |

880 |

920 |

1050 |

760 |

200 |

80 |

250 |

20 |

18 |

345 |

240 |

300 |

365 |

260 |

318 |

100 |

106 |

Φ14 |

|

MTG420/C |

1840 |

635 |

540 |

260 |

300 |

820 |

840 |

880 |

920 |

1050 |

760 |

210 |

80 |

300 |

20 |

18 |

345 |

240 |

300 |

365 |

260 |

318 |

100 |

106 |

Φ14 |

|

MTG560/C |

2370 |

990 |

600 |

340 |

300 |

1000 |

1030 |

1180 |

1250 |

1270 |

970 |

350 |

125 |

350 |

24 |

22 |

505 |

400 |

460 |

405 |

300 |

360 |

115 |

90 |

Φ14 |

|

MTG700/C |

2370 |

990 |

600 |

340 |

300 |

1200 |

1230 |

1380 |

1450 |

1370 |

1070 |

350 |

150 |

400 |

32 |

22 |

448 |

368 |

408 |

488 |

408 |

448 |

150 |

136 |

Φ14 |

|

MTG1050/C |

2330 |

990 |

700 |

340 |

300 |

1400 |

1430 |

1580 |

1650 |

1460 |

1250 |

350 |

150 |

500 |

32 |

22 |

475 |

375 |

425 |

600 |

500 |

550 |

85 |

110 |

Φ14 |

|

MTG1400/C |

2780 |

1100 |

750 |

400 |

350 |

1600 |

1630 |

1780 |

1850 |

1695 |

1500 |

435 |

200 |

600 |

30 |

26 |

750 |

650 |

700 |

600 |

500 |

550 |

100 |

110 |

Φ14 |

|

MTG1750/C |

3032 |

651 |

1003 |

560 |

350 |

1680 |

1780 |

1870 |

1940 |

1425 |

940 |

350 |

150 |

700 |

24 |

25 |

850 |

750 |

800 |

790 |

690 |

744 |

200 |

124 |

Φ14 |

|

Note:1. D2The size is the hole size of furnace. 2.To take overd1、d2Grade of all flangesPN1.0,They are auxiliary gas and main gas inlet respectively |

|||||||||||||||||||||||||