- MTG/C blast furnace gas burner

- MTG/D automatic large split type gas burner series

- MTG/F generator gas burner

- MTG/J coke oven gas burner

- MTGL automatic integrated oil and gas burner serie

- MTG/N split high temperature gas burner

- MTG automatic one - piece gas burner series

- MTL/B automatic large split type light oil burner

- MTL automatic one - piece fuel burner series

- Low NOx burner

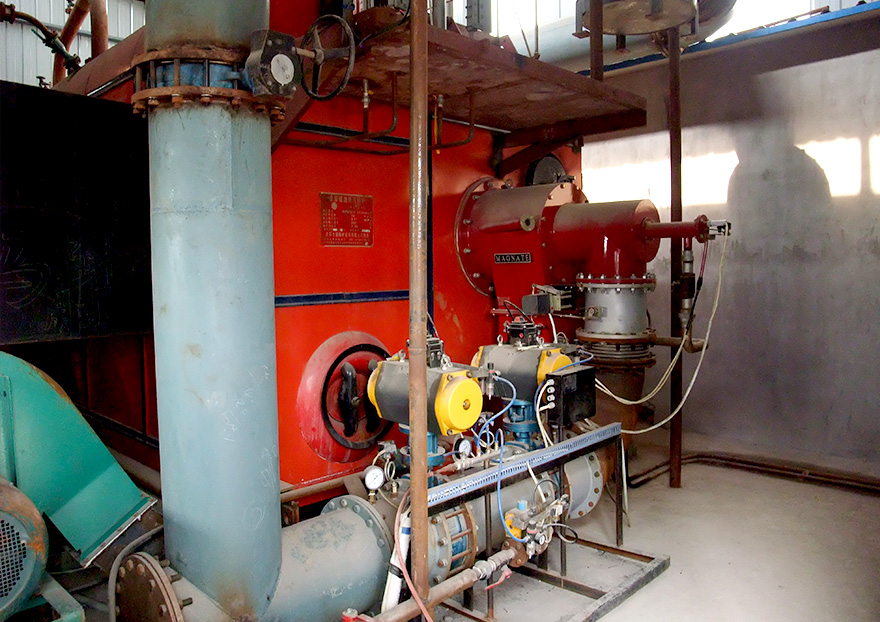

MTG/J coke oven gas burner

MTG/JCoke oven gas burner product overview:

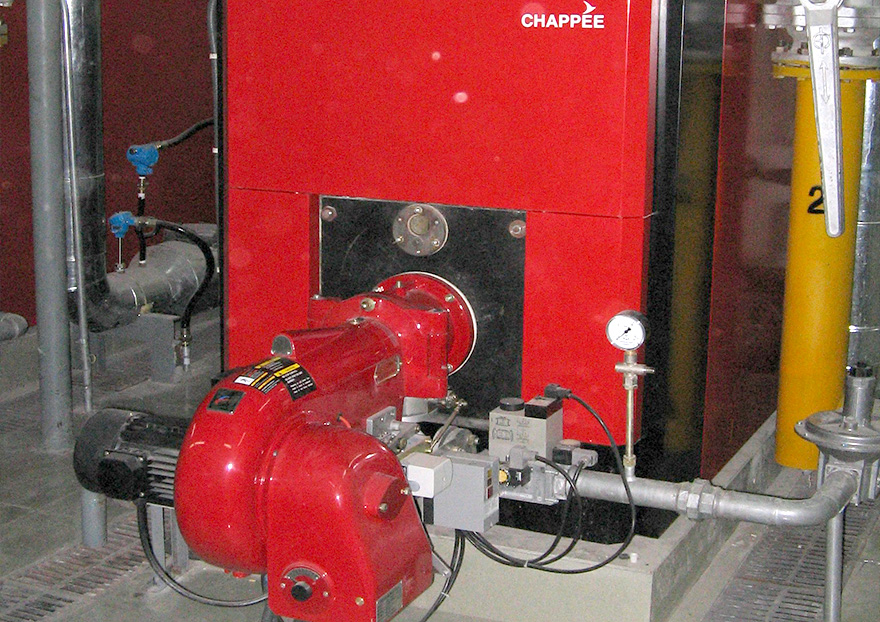

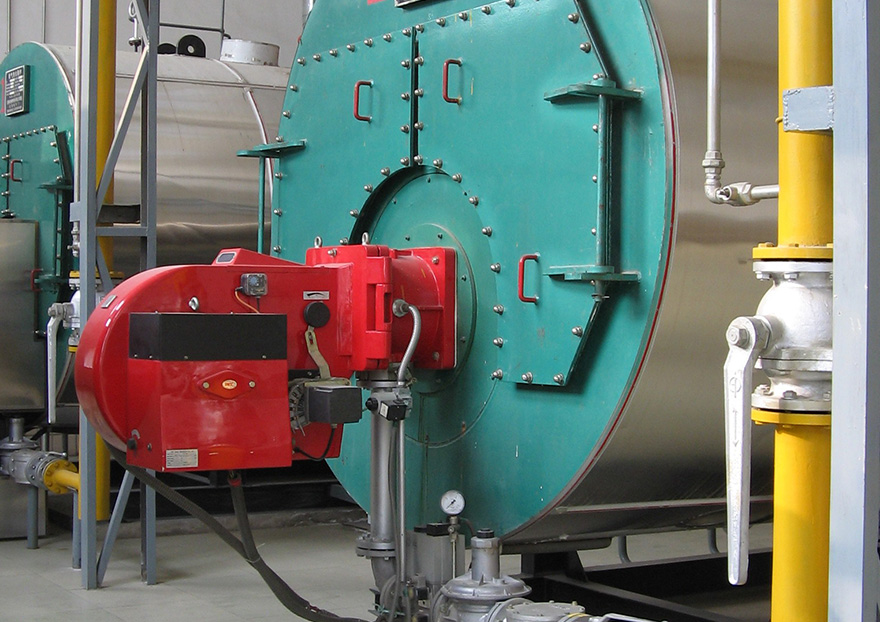

(MAGNATE)MTG/JType coke oven gas burner used in today's world of advanced combustion technology, with reference to international and domestic standards manufacturing mechanical and electrical integration of the automatic separation burning coke oven gas burner, the products are widely used in steam boiler, hot water boiler, heat conduction oil furnace, direct-fired lithium bromide air conditioning unit, air heating furnace and other industrial kiln, etc.

MTG/JThe e - type coke oven gas burner has a wide power coverage and is suitable for boiler tonnage1t/hto40t/h。

According to the requirements of the corresponding can not be adapted to the transformation250℃Below high temperature combustion air.

(MAGNATE)MTG/JFeatures of c type coke oven gas burner:

Due to the low calorific value of coke oven gas, and most of it has not been purified or treated thoroughly, the gas contains coal tar, dust and other substances that are easy to block the pipeline. Therefore, the ordinary burner cannot achieve long-term continuous operation when using coke oven gas.MTG/JSeries of coke oven gas burners for coke oven gas low calorific value, low gas pressure and high impurity content and design of the special burner, both retained the one-piece automatic burner combustion stability is good, high safety performance, but also has the coke oven gas resources can be fully and safely use of the characteristics of good product is the use of coke oven gas.

Adaptive fuel:2200kcal/Nm3≤Gas calorific value≤4500kcal/Nm3。

According to the requirements of the corresponding parts of the transformation can be adapted205℃Below high temperature combustion air.

Technical parameters:

|

Model |

尺寸(mm) |

|||||||||||

|

D1 |

D2 |

D3 |

D4 |

L1 |

L2 |

L3 |

L4 |

H1 |

H2 |

n×d |

A×B |

|

|

MTG70/J |

φ350 |

φ270 |

φ216 |

DN80 |

200 |

1185 |

270 |

388 |

540 |

305 |

4×φ18 |

200×150 |

|

MTG140/J |

φ350 |

φ310 |

φ256 |

DN100 |

230 |

1250 |

265 |

400 |

525 |

320 |

4×φ18 |

230×230 |

|

MTG280-1/J |

φ400 |

φ340 |

φ290 |

DN100 |

320 |

1335 |

250 |

410 |

525 |

320 |

4×φ22 |

260×240 |

|

MTG280/J |

φ410 |

φ360 |

φ300 |

DN100 |

280 |

1300 |

250 |

410 |

525 |

305 |

4×φ22 |

260×240 |

|

MTG350/J |

φ550 |

φ400 |

φ334 |

DN150 |

300 |

1540 |

324 |

500 |

665 |

422 |

8×φ22 |

414×314 |

|

MTG420/J |

φ550 |

φ400 |

φ334 |

DN150 |

300 |

1540 |

324 |

500 |

665 |

422 |

8×φ22 |

414×314 |

|

MTG560/J |

φ550 |

φ480 |

φ426 |

DN200 |

310 |

1625 |

390 |

490 |

705 |

483 |

8×φ18 |

400×350 |

|

MTG700/J |

φ550 |

φ480 |

φ426 |

DN200 |

310 |

1625 |

390 |

490 |

705 |

483 |

8×φ18 |

400×350 |

|

MTG1050/J |

φ718 |

φ590 |

φ537 |

DN250 |

320 |

1904 |

480 |

580 |

755 |

513 |

12×φ22 |

500×500 |

|

MTG1400/J |

φ718 |

φ600 |

φ550 |

DN300 |

320 |

2010 |

550 |

624 |

795 |

596 |

12×φ22 |

650×500 |

|

MTG1750/J |

φ980 |

φ730 |

φ680 |

DN350 |

500 |

2350 |

575 |

742 |

920 |

760 |

20×φ22 |

750×690 |

|

MTG2100/J |

φ1020 |

φ790 |

φ740 |

DN400 |

500 |

2450 |

624 |

880 |

920 |

780 |

16×φ22 |

914×794 |

|

MTG2450/J |

φ1272 |

φ900 |

φ850 |

DN400 |

500 |

2630 |

682 |

887 |

1128 |

1087 |

20×φ22 |

900×805 |

|

MTG2800/J |

φ1272 |

φ910 |

φ860 |

DN400 |

500 |

2707 |

698 |

923 |

1128 |

1087 |

24×φ22 |

1000×960 |

Note:D2For boiler front plate hole size.