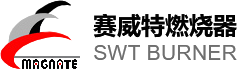

- MTG/C blast furnace gas burner

- MTG/D automatic large split type gas burner series

- MTG/F generator gas burner

- MTG/J coke oven gas burner

- MTGL automatic integrated oil and gas burner serie

- MTG/N split high temperature gas burner

- MTG automatic one - piece gas burner series

- MTL/B automatic large split type light oil burner

- MTL automatic one - piece fuel burner series

- Low NOx burner

MTGL140

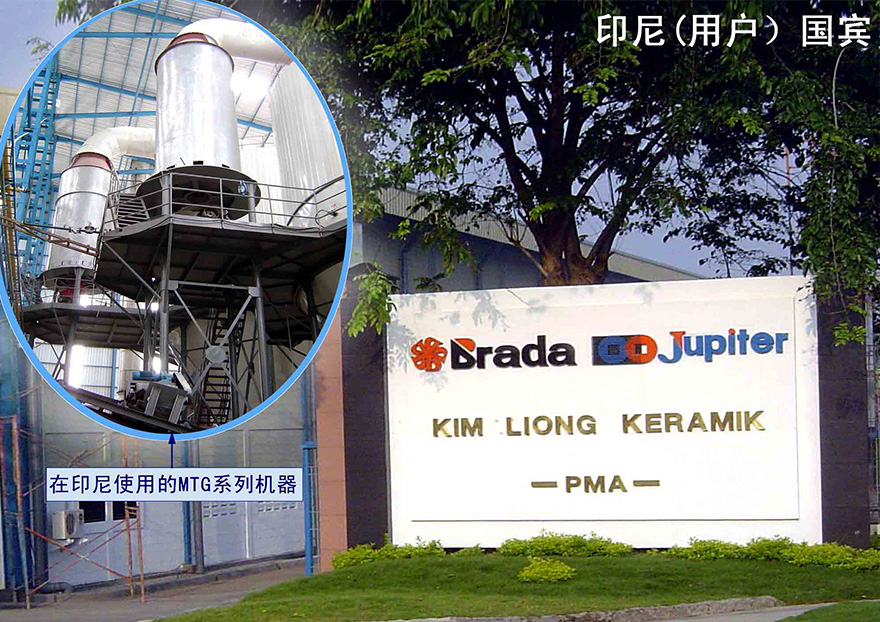

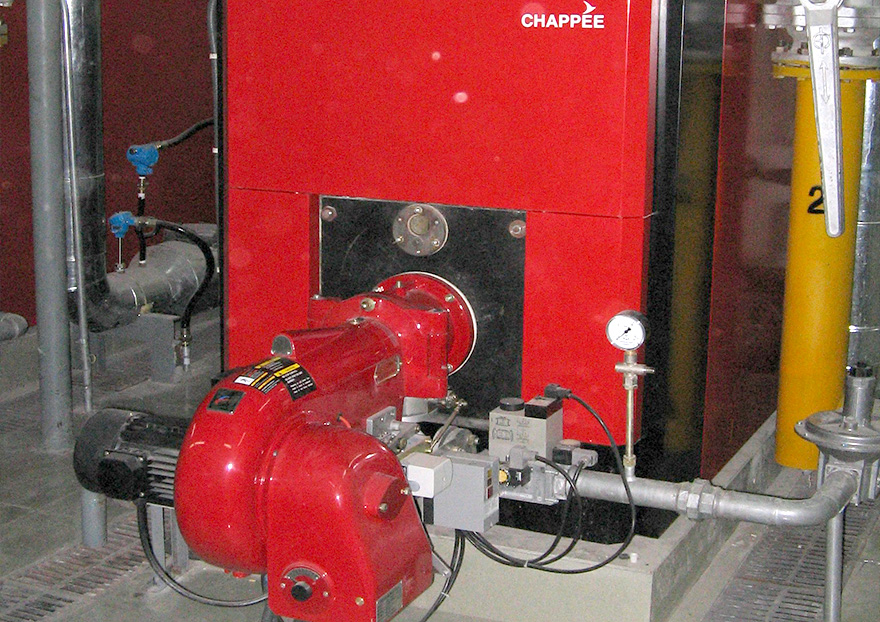

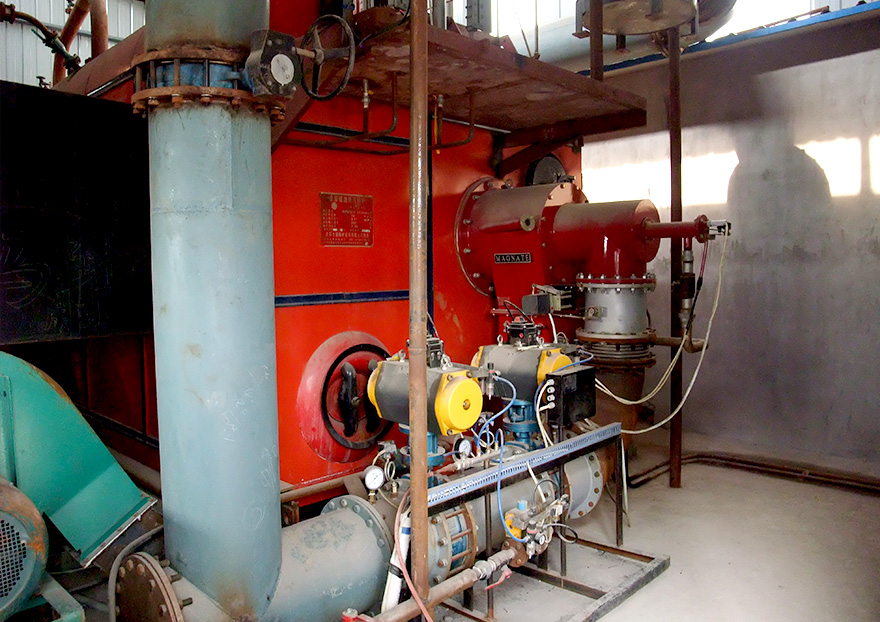

Mann grams of knight(MAGNATE)MTGLSeries dual-fuel burners are based on the world's advanced combustion technologyEN267、EN676It is widely used in steam boiler, hot water boiler, heat conduction oil furnace, direct-fired lithium bromide air conditioner, air heating furnace and other industrial kilns.

MTGLSeries dual-fuel burners are featured by exquisite structure design, simple installation, low noise and environmental protection. Users only need to connect the power supply, air source or oil circuit can be used. Simple and reliable switching between gas and fuel.

MTGLSeries dual-fuel burners are equipped with internationally renowned brands such as gas valve sets, programmed controllers, damper actuators, fuel solenoid valves, oil pumps and nozzles, etc., to ensure excellent burner performance, safe performance and reliable operation.

MTGLSeries dual-fuel burners can be applied to the calorific value is not less than4500kcal/Nm3Different classes of gas and gas matchDIN51603Standard light oil, oil viscosity:20℃for6cSt。

Mann grams of knight(MAGNATE)MTGLThe performance characteristics of series dual-fuel burners are illustrated as follows:

● Fully automatic operation, suitable for a wide range of power

● Automatic gas leakage detection, dual gas valve set

● Low running noise

● Gas pressure protection, air pressure protection

● Prepurge the furnace

● Safe flame monitoring system

● When the burner stops, the damper automatically closes

● Easy installation, commissioning and maintenance

● The conversion between different fuels is simple and the oil pump clutch is reliable.

● Environmental protection standards, ultra-low emissions.

Installation dimensions(Installation Dimensions):

|

Model |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

B1 |

B2 |

B3 |

B4 |

B5 |

H1 |

H2 |

H3 |

H4 |

D1 |

D2 |

D3 |

D4 |

D5 |

D6 |

D7 |

|

MTGL140 |

970 |

233 |

245 |

225 |

55 |

118 |

253 |

8 |

500 |

328 |

394 |

234 |

310 |

560 |

413 |

243 |

182 |

330 |

230 |

DN60 |

265 |

M12 |

298 |

270 |

Technical parameters:

Model MTGL140 |

Natural Gas |

Town Gas |

LPG |

Light oil |

Capacity kW Mcal/h |

400~2250 344~1935 |

400~2025 344~1742 |

475~2250 409~1935 |

652~2135 560~1836 |

Power supply |

380V 3/N/PE 50Hz |

|||

Rated power of motor Operation current Speed Insulation Protection |

4KW 8A 2880rpm B IP55 |

|||

Regulation mode |

Slide two-stage |

|||

Sequence controller |

LFL1.322&LGK16*** |

|||

Ignition transformer |

2×5000V |

|||

Oil pump |

J7 |

|||

Flame size Φmm×L mm |

740×3000 |

|||

Burner weight |

92kg |

|||

* The viscosity of light oil is 6cSt (1.5ºE)

**When the fuel is gas.

*** For burners that operate continuously

Diagram of the relationship between the output power of the burner and the pressure in the combustion chamber

Thick solid line for high load, thin solid line for low load