- MTG/C blast furnace gas burner

- MTG/D automatic large split type gas burner series

- MTG/F generator gas burner

- MTG/J coke oven gas burner

- MTGL automatic integrated oil and gas burner serie

- MTG/N split high temperature gas burner

- MTG automatic one - piece gas burner series

- MTL/B automatic large split type light oil burner

- MTL automatic one - piece fuel burner series

- Low NOx burner

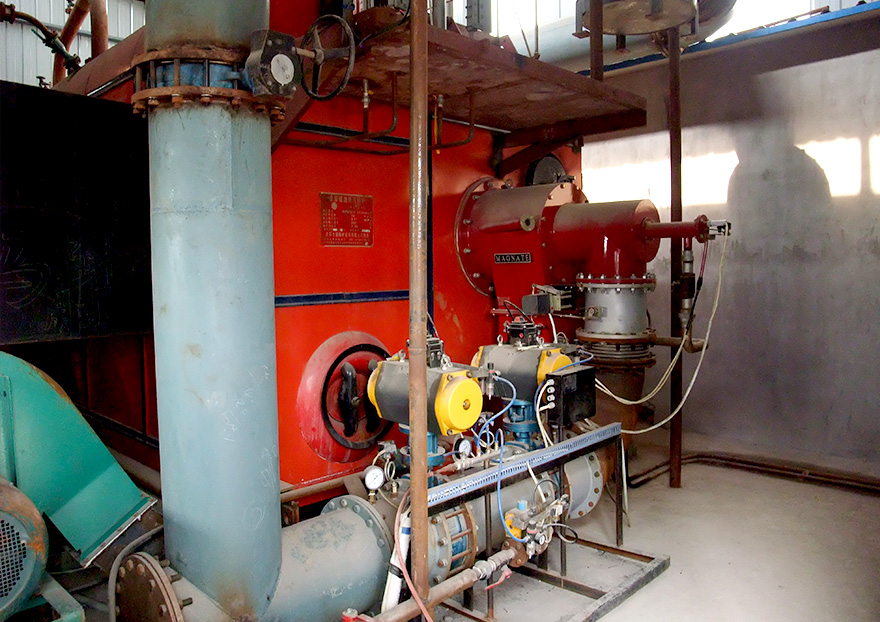

MTG/D burner

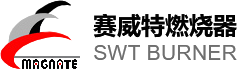

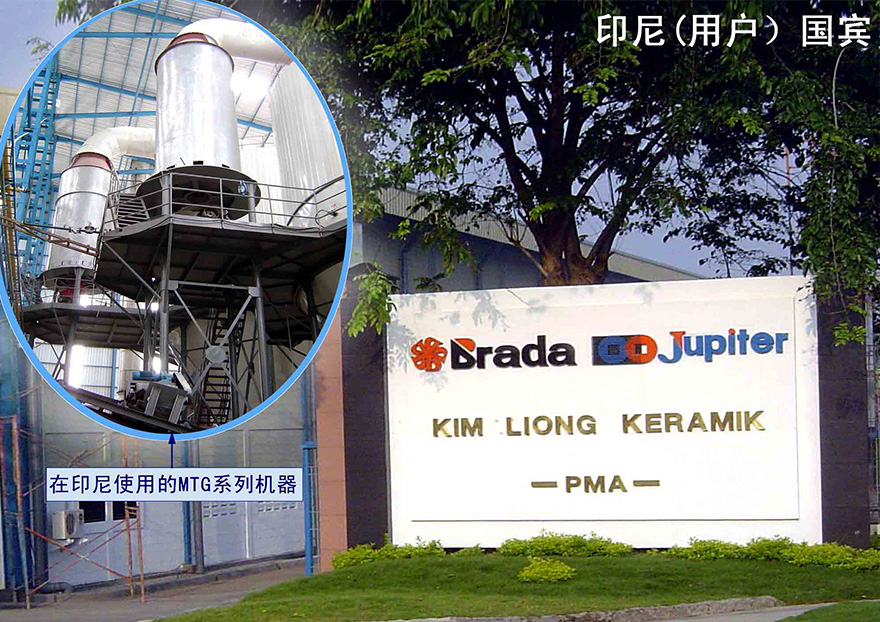

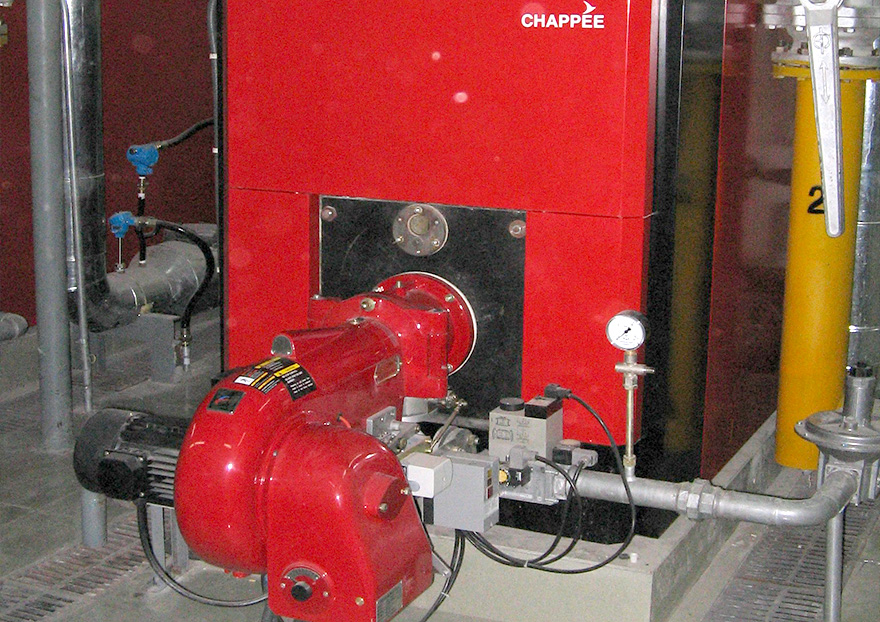

MAGNATEMTG/DType burner used in today's world of advanced combustion technology, with reference to international and domestic standards manufacturing mechanical and electrical integration of the automatic fission gas burner, the type of burner fuel gas changes in continuous mode, control system equipped with load ratio control instrument becomes continuous proportional control, proportional control instrument is not equipped with load, sliding mode for two stage. The products are widely used in steam boilers, hot water boilers, heat conduction oil furnaces, direct-fired lithium bromide air conditioning units, air heating furnaces and other industrial furnaces.

MTG/DType v combustor gas valve set, program controller, damper actuator and so on all adopt the international famous brand, guarantees the combustor performance fine, the safety performance guarantees, the movement is reliable.

MTG/DType v burner has low noise and meets the environmental protection requirement.

MTG/DType v burners are suitable for different types of gas.

MTG/DThe type v burner can change the rotation Angle of the intake air by adjusting the intake air Angle of the cyclone blade so as to adjust the geometric size of the flame.

MTG/DType v burner can be selected to adapt to different boiler chamber back pressure, even if the furnace chamber back pressure is high, but also maintain a stable and non-pulsating combustion.

MAGNATEMTG/DSeries gas burnersThe performance characteristics ofExamples are as follows:

● Fully automatic operation, suitable for a wide range of power

● Automatic gas leakage detection, dual gas valve set

● Gas pressure protection, air pressure protection

● Prepurge the furnace

● Safety flame monitor system, burner equipped with double flame monitor, with double protection

● The geometry of the burner flame is adjustable

● Adaptive fuel: calorific value of gas>4500kcal/Nm3。

● According to the requirements of the corresponding parts of the transformation can be adapted250℃Below high temperature combustion air.

● Easy installation, commissioning and maintenance

● SiemensLMVElectronic proportional control system(optional)

● The flue gas oxygen quantity feedback regulation realizes the energy saving(optional)

● Environmental protection standards, ultra-lowNOxemissions(optional)

Technical parameters:

|

Model |

MTG840/D |

MTG1050/D |

MTG1400/D |

MTG1750/D |

MTG2100/D |

MTG2450/D |

MTG2800/D |

MTG3500/D |

|

Capacity MW |

10.5 |

14 |

18.6 |

23.2 |

27.8 |

32.5 |

33.6 |

42 |

|

Fuel |

Natural gas, liquefied gas, city gas, waste gas, etc |

|||||||

|

Power supply |

380V 3/N/PE 50HZ |

|||||||

|

Regulation mode |

Slide two-stage or proportional control |

|||||||

|

Sequence controller |

LFL1.322&LGK16* |

|||||||

|

Ignition transformer |

2×7000V |

|||||||

* For burners that operate continuously

Flame size:

Installation Dimensions:

|

Model |

MTG840/D |

MTG1050/D |

MTG1400/D |

MTG1750/D |

MTG2100/D |

MTG2450/D |

MTG2800/D |

MTG3500/D |

|

D1 |

φ508 |

φ538 |

φ640 |

φ690 |

φ750 |

φ830 |

φ880 |

Φ940 |

|

D2 |

φ878 |

φ878 |

φ1258 |

φ1298 |

φ1620 |

φ1620 |

φ1620 |

Φ1750 |

|

L1 |

260 |

260 |

400 |

400 |

500 |

500 |

500 |

680 |

|

L2 |

1500 |

1500 |

1860 |

1860 |

2270 |

2270 |

2270 |

2500 |

|

L3 |

420 |

420 |

459 |

459 |

638 |

638 |

638 |

664 |

|

L4 |

1020 |

1020 |

1052 |

1052 |

1525 |

1525 |

1525 |

1426 |

|

H1 |

720 |

720 |

877 |

877 |

1112 |

1112 |

1112 |

1254 |

|

H2 |

932 |

932 |

1119 |

1119 |

1376 |

1376 |

1376 |

1538 |

|

A×B |

547×462 |

547×462 |

758×566 |

758×666 |

914×794 |

914×794 |

902×780 |

1290×800 |

|

n-d |

16-φ22 |

16-φ22 |

20-φ18 |

20-φ18 |

20-φ22 |

20-φ22 |

20-φ22 |

20-φ22 |