Waste heat must not be wasted the boiler must be reformed

2022-05-06 10:36:56

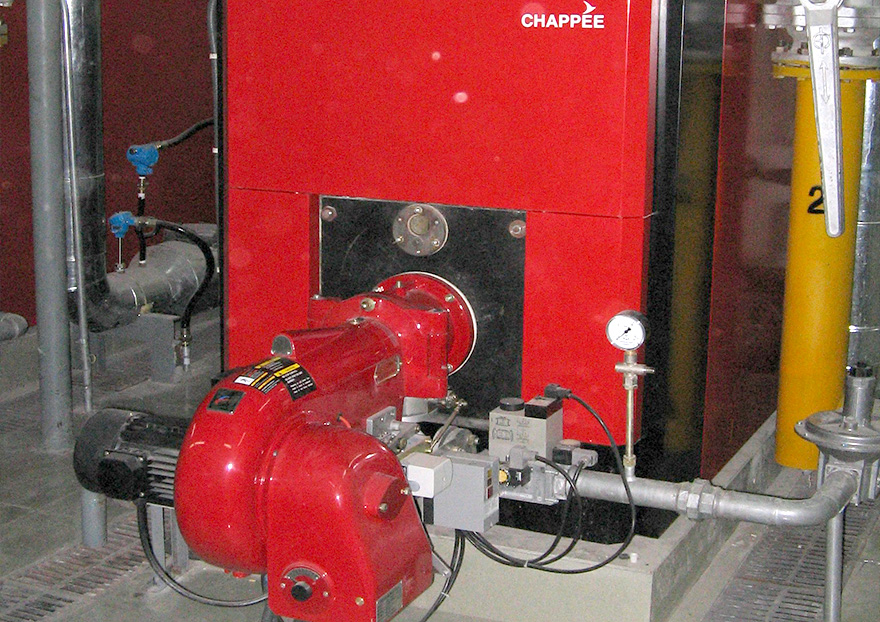

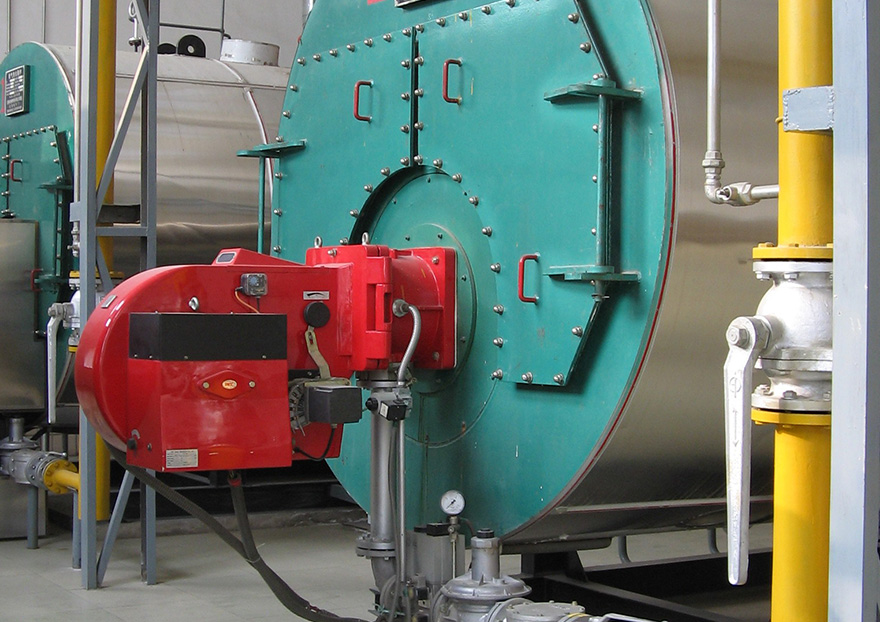

First, add fuel economizer

After the fuel economizer treatment of hydrocarbons, fuel viscosity decreased, the fuel oil atomization, refined, to improve greatly before combustion, spray into the combustion chamber internal been fully under the condition of low oxygen combustion, thus the blast volume of combustion equipment can reduce 15% to 20%, avoid to take away the heat in the flue, flue temperature drop 5 ℃ to 10 ℃. The fuel oil of combustion equipment can save 4.87% to 6.10% due to the improvement of combustion efficiency after being treated by energy saver, and the flame is bright and dazzling, the black smoke disappears, and the furnace is clear and transparent. Completely remove the coking phenomenon of combustion oil tip and prevent re-coking. Eliminate the phenomenon of residual accumulation in furnace wall due to insufficient combustion of fuel to achieve the effect of environmental protection and energy saving. Greatly reduce the exhaust gas from combustion equipment to air pollution, carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC) and other harmful components in the exhaust gas greatly reduced, the discharge of harmful exhaust gas reduced by more than 50%. At the same time, the dust content in the exhaust gas can be reduced by 30%-40%. Installation position: installed between the oil pump and the combustion chamber or nozzle, the ambient temperature should not exceed 360℃.

Two, the installation of condensing gas boiler energy saver

Condensing gas boiler energy-saving device can be directly installed in the existing boiler flue, recovery of high temperature flue gas energy, reduce fuel consumption, economic benefits are very obvious, at the same time the condensation of water vapor to absorb nitrogen oxides, sulfur dioxide and other pollutants in flue gas, reduce pollutant emissions, has important environmental protection significance.

Three, the use of condensing waste heat recovery boiler technology

The thermal efficiency of boiler is calculated by the low calorific value of fuel without considering the heat loss of latent heat of vaporization in the high calorific value of fuel. Therefore, the thermal efficiency of the traditional boiler can only reach 87% ~ 91%. And the condensing waste heat recovery boiler, it reduces the exhaust temperature to 50 ~ 70℃, fully recover the sensible heat in the flue gas and water vapor condensation latent heat, improve the thermal efficiency; Condensate can also be recycled.

Fourth, the boiler tail adopts heat pipe waste heat recovery technology

Waste heat is the energy that has not been used in the energy utilization equipment under certain economic and technical conditions, that is, the redundant and discarded energy. It includes high temperature waste gas waste heat, cooling medium waste heat, waste steam waste water waste heat, high temperature products and slag waste heat, chemical reaction waste heat, combustible waste gas waste liquid and waste heat and high pressure fluid residual pressure. According to the survey, the total waste heat resources of various industries account for about 17%-67% of their total fuel consumption, and the recoverable waste heat resources account for about 60% of the total waste heat resources. Superconducting heat pipe is the main heat conduction element of heat pipe waste heat recovery device, which is essentially different from common heat exchanger. The heat exchange efficiency of the heat pipe waste heat recovery device can reach more than 98%, which is beyond the reach of any common heat exchanger. Heat pipe waste heat recovery device is small in volume, only 1/3 of the common heat exchanger. The waste heat recovery device composed of a number of heat pipes is installed in the boiler flue port, which absorbs the heat in the flue gas and conducts it to the other end at a high speed, so that the exhaust temperature drops to the dew point and reduces the heat emission loss. The heated clean air can be dried materials or added to the boiler for circulation. Improve the thermal efficiency of boilers and industrial furnaces, reduce fuel consumption, achieve the purpose of energy saving.

In the design and manufacture of industrial fuel oil, gas and coal-fired boilers, in order to prevent the corrosion and ash blocking of the heating surface of the boiler tail, the standard exhaust temperature is generally not less than 180℃, up to 250℃, high temperature flue gas emissions not only cause a lot of waste of heat energy, but also pollute the environment. The heat pipe waste heat recovery device can recover the heat of flue gas. The recovered heat can be used as water supplement and domestic water for boiler, or heated air for boiler combustion air or drying materials. Save fuel costs, reduce production costs, reduce exhaust emissions, energy conservation and environmental protection. The reconstruction investment is recovered in 3-10 months, and the economic benefit is remarkable.

Five, the use of scale prevention, descaling technology

Through the use of boiler scale remover, electronic scale inhibitor and softening water treatment equipment, optimize the water vapor circulation system, softening water equipment can remove calcium, magnesium and other scaling ions in water, make water softening, reasonable control of boiler sewage rate, so as to reduce scale, improve the boiler thermal efficiency.

Adopting fuel additive technology

Adding additives to fuel can optimize fuel, reduce smoke scale and improve thermal efficiency.

Use of new fuels

The new environmental protection fuel oil can reduce fuel cost.

Eight, the use of oxygen-rich combustion technology

The oxygen content in the air is less than or equal to 21%. The combustion of industrial boilers is also carried out under such air. Practice shows that when the amount of oxygen in boiler combustion reaches more than 25%, the energy saving is up to 20%. Boiler start temperature rise time is shortened 1/2-2/3. Oxygen enrichment is the application of physical methods to collect oxygen in the air, so that the oxygen content in the collected gas is 25% - 30%. Oxygen-enriched combustion is a new technology of energy saving and environmental protection. In recent decades, with the continuous improvement of environmental protection requirements and the need to save energy, oxygen-rich combustion as a new combustion technology in the world flourish.

Using cyclone combustion boiler technology

Compared with traditional industrial boilers, the new technology of pure smokeless and energy-saving swirl combustion boiler has absolute advantages. It saves 30%~35% coal than hand fired boiler and 25% coal than chain automatic boiler. Due to pure smokeless and energy-saving energy-saving technology used PID frequency conversion and the ABM system, power saving 40% than traditional boiler, antioxidant1010 can achieve more than 90% of the combustion and utilization, and volatilization of traditional boiler burning rate is only about 78%, 22% of the dust into the atmosphere, pure smokeless energy-saving vortex combustion technology to make ash burning rate reached 97%, And the traditional boiler coal slag burning rate is only about 80%, it is because of these reasons, pure smokeless energy-saving combustion technology can make the furnace temperature from the original 1200℃ to 1500℃, improve the combustion efficiency, save fuel, to meet the needs of customers.

Ten, the use of air source heat pump hot water unit replacement technology

Replace the existing oil (gas) hot water boiler with air source heat pump hot water unit; Energy consumption can be saved by 30-50%.