Analysis on existing problems of energy saving and emission reduction of industrial boilers and thei

2022-05-06 10:38:10

Our energy industry, our steel industry. As well as collective heating in the north in winter, boilers are used. The structure of industrial boiler has helped the development of our industry. Once upon a time, the tall chimney of boiler is the proof of development. But with people's understanding of environmental protection, as well as the continuous development of energy industry and industrial industry, industrial boiler is gradually criticized by people for its high waste of resources and emission of pollutants. But the development of industry and People's Daily life is still inseparable from the use of industrial boilers, so it is very important to improve the energy efficiency of boilers, reduce the emission of pollutants, change the original boiler waste a lot of energy phenomenon. At the same time learn to use the heat energy in the chimney, do a good job of the secondary utilization of energy, is the need to have a clear understanding of the problems of the existing boiler, and then put forward the corresponding industrial boiler rectification measures. Realize the purpose of protecting the environment and saving energy.

1. Problems existing in industrial boilers

1.1 Design defects of industrial boilers themselves

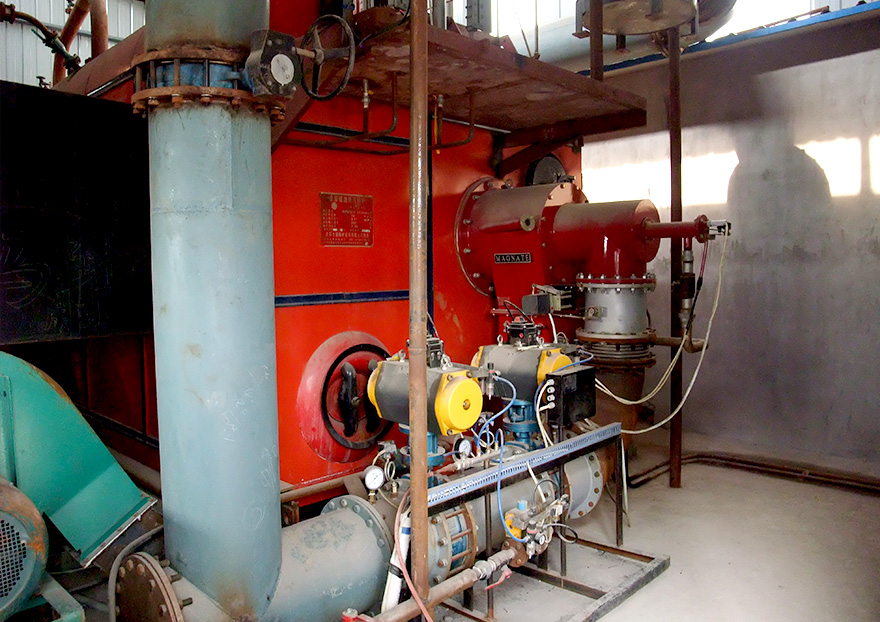

In order to improve the energy utilization rate of industrial boilers and reduce the emission of pollutants, it is necessary to understand the structure and nature of industrial boilers, so as to realize the energy conservation and emission reduction of industrial boilers. First of all, the industrial boiler equipment has great defects, which are determined by the nature of nature. Even if the energy saving and emission reduction work is done well, there is a certain limit of the energy conversion rate. Industrial boilers have many characteristics. First of all, the capacity of industrial boilers is small, because the use of iron casting, so it is limited by volume. In addition, industrial boilers in long-term use will appear a large number of coking heating surface, dust accumulation, serious image of the heat transfer rate of the boiler, so that the heat conversion capacity of the industrial boiler is very high temperature, there is a lot of heat energy, these heat energy are wasted in the air, resulting in a great waste of energy. Industrial boilers also have the problem of excessive water pollutants. Many of China's industrial boilers do not have the corresponding self-control system, the intelligent level is low, in addition to a lot of boiler quality is not guaranteed, not only pollution of the environment, at the same time the use of boiler residents heating institutions, waste a lot of resources, or the use of boiler production enterprises to get the product quality is often unqualified.

1.2. Problems existing in energy conservation and emission reduction of industrial boilers

The energy saving and emission reduction of industrial boilers need to be carried out from many aspects at the same time. In the development of industry, the work efficiency of industrial boilers is controlled by five factors, which are personnel, fuel, boiler itself, automation equipment, and control technology. People are the principle personnel of the boiler, and their corresponding quality level affects the efficiency of the boiler, and is also related to whether the boiler can be found in the first time when there is a problem, which is important for the use of the boiler. Fuel is the energy of combustion, energy and boiler matching, if too much energy will cause unnecessary waste, in addition, insufficient energy will affect the quality of products, as well as produce greater pollution. The control technology should realize the real-time monitoring of the boiler, and inform the relevant personnel when problems occur. Automation is the problem of controlling the flow in boiler operation,

First, industry related personnel and implement energy conservation and emissions reduction work related personnel failed to fully recognize the impact of the five elements of the problems in the energy conservation and emissions reduction, thus failed to people, materials, furnace, machine, control the five elements as a systems engineering comprehensive coordinated development, and long-term overall planning of all problems and find out the method to solve the problem.

Secondly, the energy policies issued by the relevant departments of the state and the relevant social public opinion environment failed to form practical pressure on the energy conservation and emission reduction work of the industrial boiler industry. On the one hand, relevant departments failed to take corresponding measures to publicize the importance of coal and other non-renewable energy, on the other hand, they did not take strict control of the development and utilization of non-renewable resources, so that the industry personnel did not form an important understanding of the urgency of this work. At the same time, the public does not have a clear understanding of the pollution caused by industrial boilers, and there is no public opinion pressure on the industry to save energy and reduce emissions.

Third, the use and management level of industrial boilers is low, and the overall quality of operation personnel needs to be improved. At present, our country industrial boiler operation personnel technical quality is generally low phenomenon exist, most of the industrial boiler operation personnel lacks a comprehensive and systematic for boiler technical training and learning, not completely effective control of industrial boiler operation skills, lack of corresponding industrial boiler maintenance methods, thus affecting the effective use of industrial boiler, It also brings some difficulties to the energy saving and emission reduction of industrial boilers.

Finally, the level of automatic control device for industrial boiler operation is very low. At present, there is no operation monitoring instrument in the industrial boiler, which leads to the waste of the relevant operators who can not adjust the boiler operation condition according to the load change when adjusting the boiler combustion condition.

2, promote industrial boiler energy conservation and emission reduction countermeasures

2.1 Establish and improve the energy conservation and emission reduction index system at the policy level, and build a dynamic energy conservation supervision system.

Local governments at all levels shall formulate supporting measures and preferential policies to encourage energy conservation and emission reduction and promote the development of new energy, carry out publicity and education on energy conservation of boilers and other special equipment, create a good working atmosphere, raise the general public's awareness of energy conservation and emission reduction, and jointly promote the energy conservation and emission reduction work of industrial boilers.

2.2 At the policy level, accelerate the improvement of laws and regulations on energy conservation and emission reduction, and improve the punishment standards.

Relevant law enforcement departments should speed up the perfect legal system for energy conservation and emissions reduction, enhance punishment standard, focus on solving the illegal cost is low, the law to the problem of high cost, thus make the public aware of the fuel is public resources, is also a scarce resource, not free to use, must be used to save fuel, fuel use.

2.3 Promote frequency conversion technology with low power consumption on the technical level.

Because industrial boilers are manually regulated by operators with their own experience in the process of operation, the peak energy consumption waste caused by this is large. If can adopt frequency control of motor speed technology, can reduce the speed of the motor, reduce mechanical wear and tear, reduce the working temperature of the motor, thus reducing maintenance workload, at the same time, the motor with soft start, the starting current gradually increased from zero to rated current value, so can not only energy saving but will not cause impact to power grid, greatly increase the energy saving effect.

2.4 The management shall establish and improve the regulations and standards for industrial boilers, and form the consensus of the whole society on energy conservation and emission reduction

Related industries leading personnel to find innovation breakthrough from the management, so as to make management of industrial boiler energy conservation and emissions reduction of soft power, national policy department to establish and improve our policy in industrial boiler fuel, energy-saving products, energy efficiency label each layer in the regulatory standards, such as making industrial boiler energy conservation and emissions reduction work based on the good environment of social supervision, Finally form the consensus of the whole society to save energy and reduce emission.

2.5 Improve the professional ethics of industry technicians and guide the energy conservation and emission reduction work of industrial boilers with innovative technologies.

We should improve the technical quality and professional ethics of the operation personnel of industrial boilers in China, carry out comprehensive and systematic technical training and learning for the operation personnel of industrial boilers, so that they can fully and effectively master the operation skills of industrial boilers and the corresponding maintenance methods of industrial boilers.

3, summarize

Industrial boiler with the development of China's industry, now people gradually realize that industrial boiler energy utilization rate is low, at the same time more serious pollution, not meet the requirements of China's energy conservation and emission reduction. Therefore, it is necessary to transform the problems of industrial boilers. Five aspects should be carried out simultaneously. First, quality management of personnel should be strengthened. Second, the structure of the boiler itself is reformed, while improving the corresponding quality. Third, to carry out a scientific calculation of the relationship between fuel and boiler, find the energy suitable for different boiler equipment, so as to reduce the waste of energy and protect the environment. In the fourth. The corresponding auxiliary equipment is reformed to make it more conducive to the operation of the boiler. Fifth, the use of effective control and management means to help the boiler to maximize capacity.