The use, debugging and matters needing attention of gas burner

2022-04-30 09:15:54

Phenomenon, cause and treatment of fuel burner faults:

First, the burning rod of the burner does not burn

The reason:

1. The incinerator rod is filled with carbon residue and oil pollution.

2, burning rod broken. Damp. The leakage.

3. The spacing between burning rods is not correct, too long or short.

4, incineration rod insulation skin damage, short circuit to the ground.

5, incineration cable and transformer faults: cable break, connector damage to form a short circuit during ignition; Transformer disconnection or other faults.

Treatment: 1, clear. 2, new. 3. Adjust the interval. 4. Change the wire. 5, replace the line, replace the transformer.

Two, the burning rod sparks but does not ignite

1. The ventilation gap of the cyclone disc is blocked by carbon deposition, and the ventilation is poor.

2. The oil nozzle is unclean, blocked or worn.

3. The damper setting Angle is too small.

4, the incineration rod tip from the leading edge of the oil nozzle spacing is not appropriate (too outstanding or shrinkage)

5, the first oil is blocked by debris (small fire gun).

6. The oil is too viscous to flow easily or the filter system is blocked or the oil valve is not opened, so that the oil pump lacks oil absorption and the oil pressure is low.

7. The filter screen of the oil pump is blocked.

8, the oil contains more water (boiling noise in the heater).

Treatment: 1, clear. 2, first clean, if not for new. 3. Small adjustment experiment. 4, adjust the interval (3~4mm is the best). 5. Remove and clean (clean the parts with diesel oil). 6, check the pipeline and oil filter, insulation equipment. 7. Remove the outer screw of the oil pump, carefully remove the outer cover and take out the oil net inside, and soak it with diesel oil. 8. Try new oil.

Three, small fire normal and turn to fire, calm or flame shining instability.

The reason:

1. The air volume setting of the damper of the fire is too large.

2. The micro switch of the oil valve of the fire (the outermost group of the damper) is not set properly (it is set to be larger than the air volume of the damper of the fire).

3, oil viscosity is too high and not easy to atomize (heavy oil).

4, the distance between the cyclone plate and the nozzle is not proper.

5, fire nozzle wear or dirty.

6. The heating temperature of the reserve tank is too high, resulting in the failure of the oil pump and oil delivery due to steam.

7, oil water.

Treatment methods: 1, gradually reduce the experiment. 2, D ⅰ ≡D ⅱ + (5°~10°), forbidden: D ⅰ ≡D ⅱ, D ⅰ < D ⅱ. 3, improve the heating temperature. 4, adjust the interval (between 0~10mm). 5. Clean or replace. 6, set about 50℃ can be. 7, oil change or drainage

Four, the noise of the combustion machine increases

The reason:

1. The cut-off valve in the oil circuit is closed or the oil intake is insufficient, and the oil filter is blocked.

2, the inlet temperature is low, the viscosity is too high or the pump inlet temperature is too high.

3. The oil pump shows problems.

4, fan motor bearing damage.

5, the fan impeller is too dirty.

Solution: (1) Check whether the valve in the oil pipeline is opened, whether the oil filter works normally, and clean the filter net of the pump itself. ② Increase or decrease the oil temperature. Replace the oil pump. Replace the motor or bearing. Clean the fan impeller.

Five. The burner burns badly

(1) Thick black smoke rises when a small fire is lit

Reasons: 1) Small fire door setting is too small.

2) Oil nozzle wear, poor atomization.

3) ⑧ Improve the heating temperature. ④ Adjust the interval (between 0 and 10mm) : clean or more about 50~C can be. 7. Oil change or drainage.

4. The noise of the burner increases

Cause: 1) The cut-off valve in the oil circuit is closed or the oil intake is insufficient, and the oil filter is blocked.

2) The inlet temperature is low, the viscosity is too high or the pump inlet temperature is too high

3) The oil pump presents problems. |

4) The bearing of the fan motor is damaged.

5) The fan impeller is too dirty.

Solution: (1) Check whether the valve in the oil pipeline is opened, whether the oil filter works normally, and clean the filter net of the pump itself. ② Increase or decrease the oil temperature. Replace the oil pump. Replace the motor or bearing. Clean the fan impeller

Six. Burning of bad

(1) Thick black smoke rises when a small fire is lit

Reasons: 1) Small fire door setting is too small.

2) Oil nozzle wear, poor atomization.

3) D Ⅰ D Ⅱ or less.

Treatment: ① Adjust the size of the air door. ② Replace the oil nozzle. ⑧ adjust D ⅰ ≡D ⅱ + (5°~10°).

(2) Black smoke damper adjustment is invalid

Reason: oil nozzle wear, poor atomization.

Solution: Replace the nozzle.

(3) the white smoke

Reasons: 1) The damper is too large.

2) Water seepage in the oil.

Treatment: (1) adjust the air door. ② Improve the quality of oil.

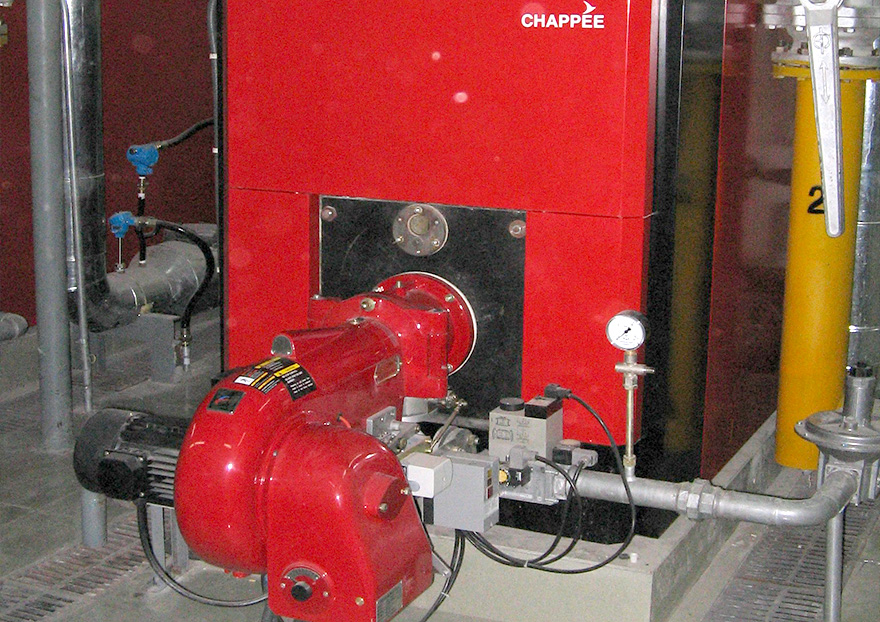

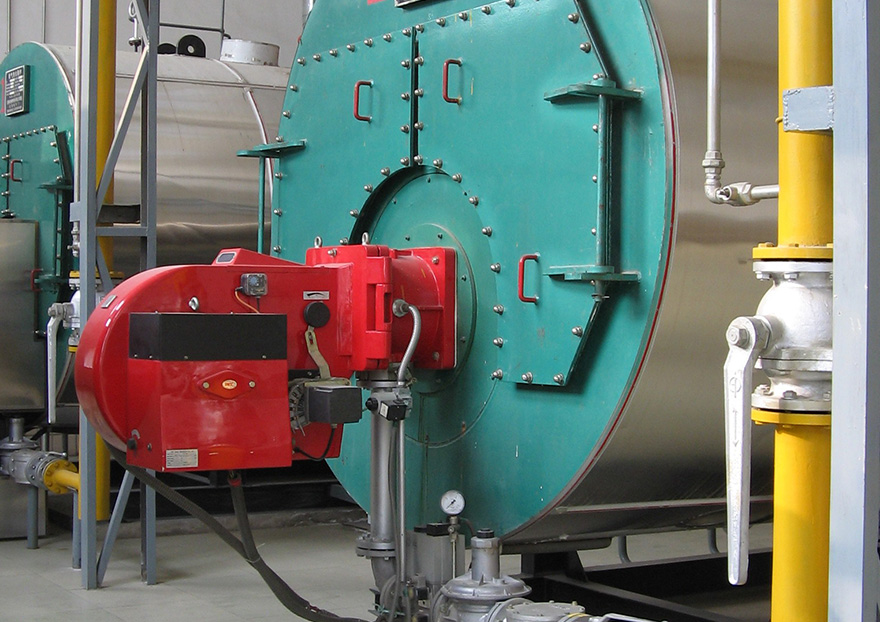

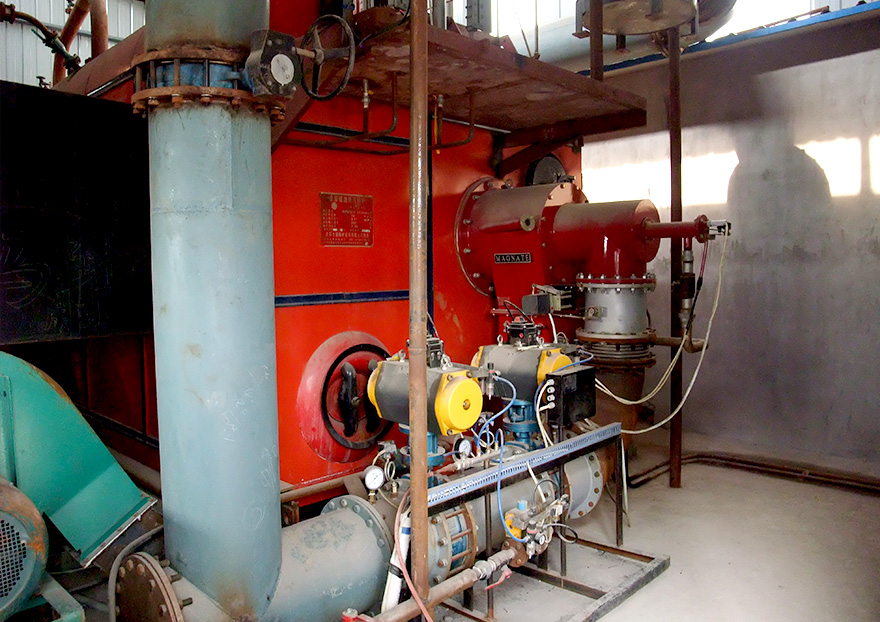

For more information about burners, please continue to pay attention to Wuxi Saiwitt Burner Manufacturing Co., LTD