What adjustments should be made to the burner

2022-04-30 09:15:54

Combustion adjustment should not only be based on theory, but also be guided by practical experience:

① Take the flame detection monitoring window as one of the main monitoring screens. Keep the combustion in the furnace stable, the flame is bright golden yellow, does not deviate, does not stick to the wall, and has good flame filling degree.

(2) Maintain the air preheater inlet oxygen in the range of 4% ~ 6%, when there is a dark red and long flame or even the chimney smoke, should adjust the boiler auxiliary wind baffle in time, organize a reasonable air distribution, maintain the best coordination of air volume and powder volume, maintain good combustion in the furnace.

③ The coal bunker coal level should be regularly monitored to prevent the coal mill from breaking due to the burning of the original coal bunker.

(4) when boiler combustion is unstable, it is strictly prohibited to start and stop the operation of boiler ash blowing and pulverizing system.

⑤ Should observe the flame on the spot, pay attention to air leakage in the furnace, all fire holes, coke holes are tightly closed.

⑥ Operation personnel should timely understand and master the characteristics of coal, coal quality change to do know, reasonable organization of combustion.

The regular observation and analysis of boiler fly ash, furnace bottom ash, timely combustion adjustment, to maintain the economic operation of the boiler.

In the direct blown pulverizing system, the boiler operating load is directly related to the output of the mill, which makes the whole pulverizing system often cannot operate under the most economic conditions. Because the output of the pulverizing system is equal to the amount of coal fired into the furnace, the change of the system ventilation volume affects the proportion of the primary and secondary air, thus affecting the stability of the boiler operation and combustion conditions in the furnace. Pulverizing system air volume, coal volume changes with the boiler operating load, and the concentration of gas powder in the system changes frequently, according to these characteristics, comprehensive consideration of various factors, effective combustion adjustment, in order to ensure the safe, stable, economic operation of the unit.

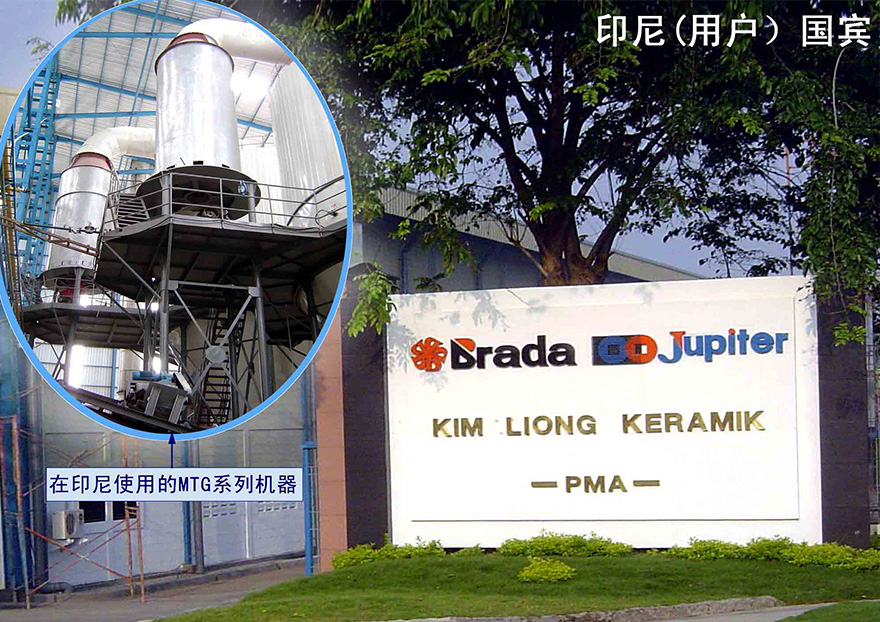

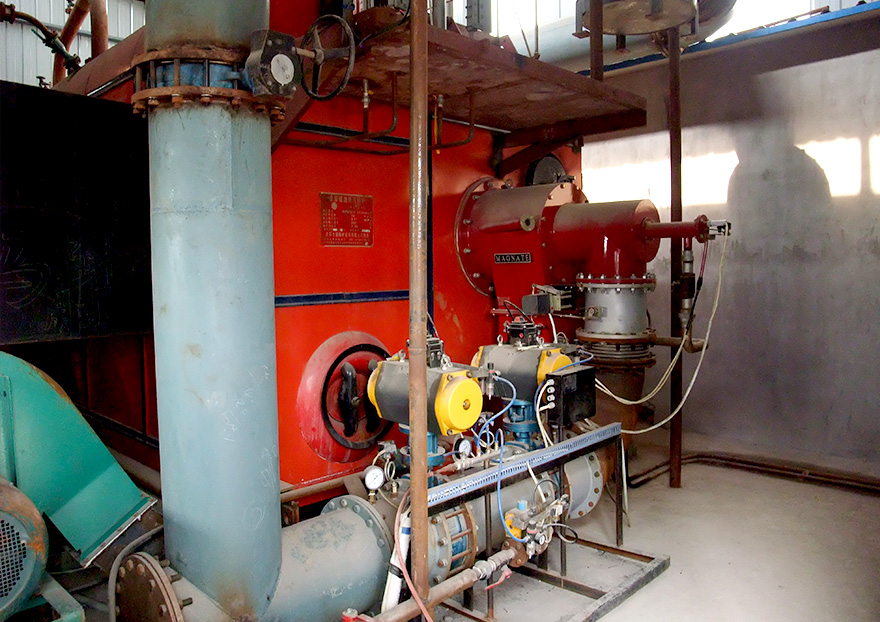

For more information about burners, please continue to pay attention to Wuxi Saiwitt Burner Manufacturing Co., LTD