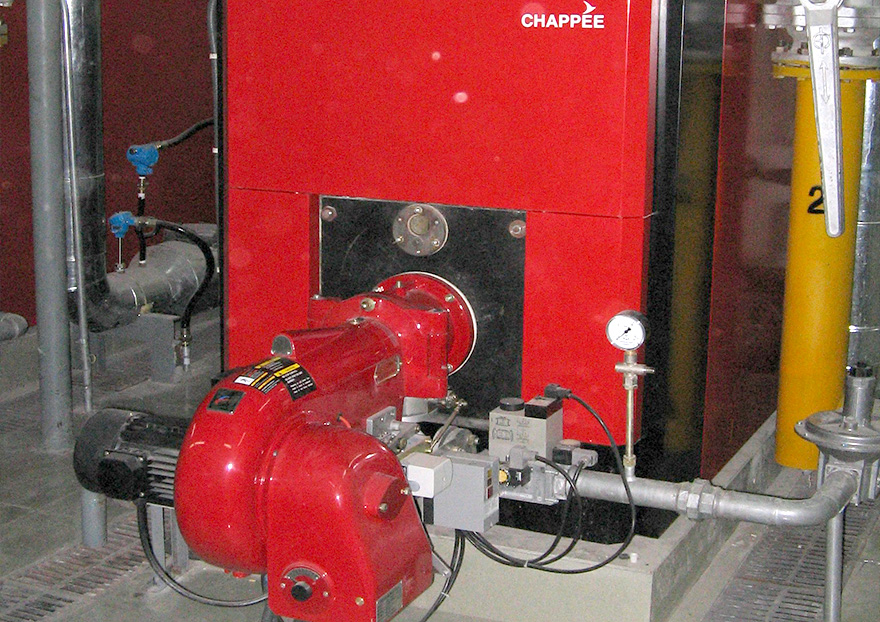

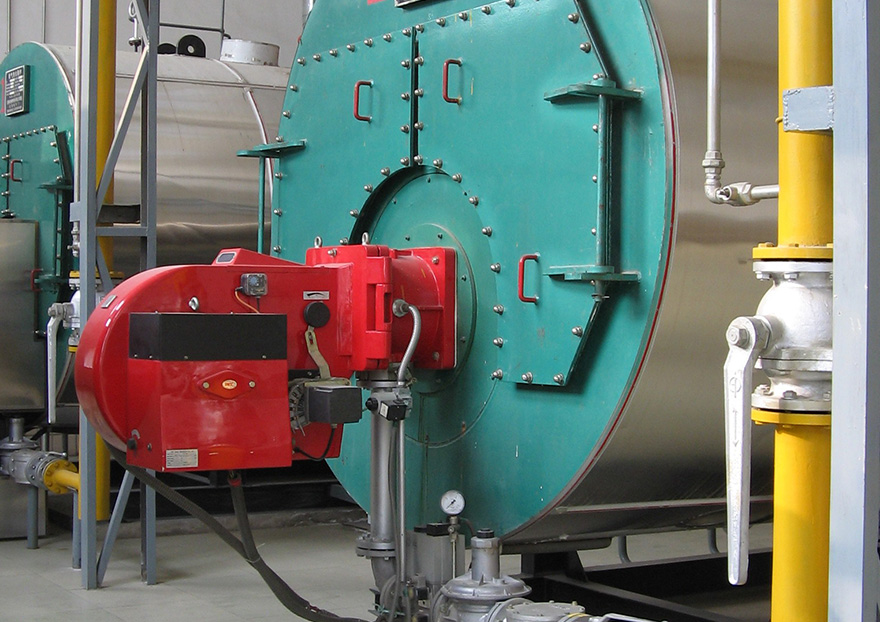

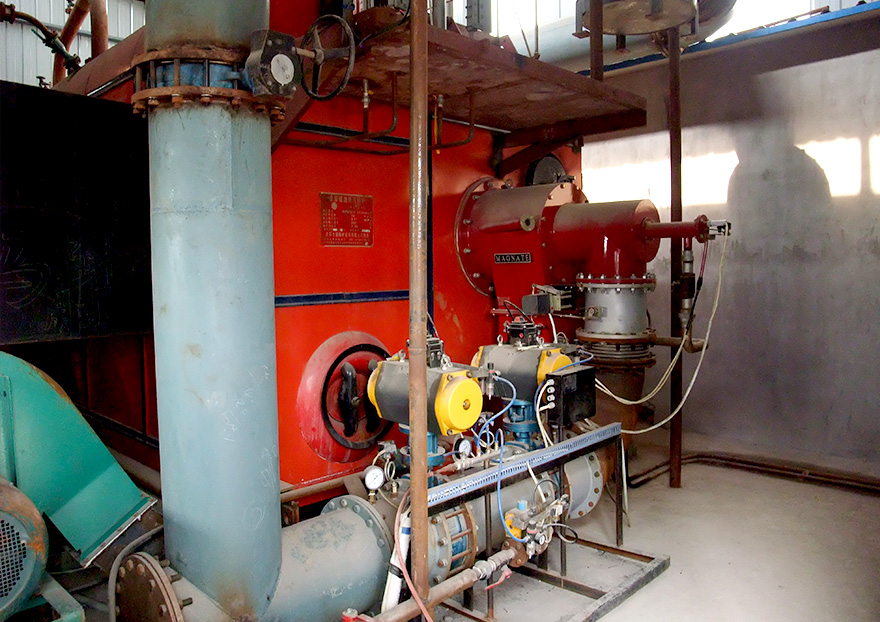

Gas boiler controller periodic maintenance inspection

2022-05-06 10:41:09

Scheduled protection twice a month:

A. Fuel supply line check: gas controller 1. Light oil filter cleaning; 2. Check the air tightness of the incineration gas pipeline; 3. Check whether the pipes are dredged.

B. Check each surface: gas controller 1. 2. Pressure gauge bend scour; Safety valve test.

C. Check the incinerator: gas controller flame detector (electric eye) cleaning surface; 2. Check whether the operating pressure of the oil pump is normal; 3. Check whether the burning flame is normal; 4. Check whether there is abnormal gas controller in the sound of the incinerator during incineration; 5. Clean the rotary plate; 6. Clean the water stick.

D. Check the water inlet system: 1. Clean the water filter. 2. Whether the pump reaches additional head and flow; 3. Check valve operation is normal.

E. Daily tank drainage and gas controller cleaning debris. Water quality test, furnace water test.

F. Check whether the incineration consumption is normal.

Protection items every three months:

In addition to the above items, the gas controller plus items:

A. Electrical part: 1. Whether the line is gas controller loose aging, failure; 2. Check whether the electrical components are reliable and overloaded; 3. Whether the electrical protection equipment is normal;

B. Open the low valve to clean up sludge when the soft water tank is out of service;

C. Testing boiler repoint interlocking gas controller: 1. Low water position; 2. The overpressure; 4. Ultra-high smoke exhaust temperature; Etc.

D. Mass smoke detection: including analysis of flue gas forming controller and detection of tail smoke temperature to check whether incineration is working normally.

E. Cleaning the boiler body and the surface cleaning of the incineration gas controller.

Annual major insurance projects:

A. Host body

Comprehensive arrangement of smoke pipe, water pipe, gas controller before and after the smoke box, furnace, burnout chamber and smoke pipe ash collection.

1. Fully open the cover to check the sealing degree of hand holes, manholes and other inspection holes, and replace the defective gaskets in time.

2. Comprehensive detection of all surfaces, valves and gas controllers, including pressure gauges, pressure controllers and electrode water level controllers, and the setting of safety valves.

B. Incinerator part:

Comprehensive arrangement of incinerator cup tray, incineration equipment, filter, oil pump, motor and impeller system, add lubricant to damper connecting rod equipment. The gas controller provides a de novo inspection of incineration status.

C. Control part

Maintenance and detection of electrical components, control line gas controller, sorting control box dust collection, each control point for testing.

D. Water supply system

Overhaul the water treatment equipment, check whether the water quality is qualified, comprehensively arrange the soft water tank, check the working condition and head of the feed pump, clean the check gas controller valve spool, etc.

1. The air-fuel ratio of the incineration machine, please adjust the gas volume to small or increase the air volume. The possible reason is that the pipeline pressure becomes larger (because the warm peak of the gas collection controller has passed, the pressure of the medium pressure pipeline is enough, which will affect the air supply pressure before the valve group of the incineration machine).

2, burning machine burning head for carbon is more, because carbon is along with the use of time to add and add, set to must thickness will affect the effect of burning gas controller, also affects the detection sensitivity of flame probe (flame probe in the principle of fire would amount to a current, more carbon deposition, would amount to a resistance, program-controlled machine test less than current will think burning loss). Clean and polish the burning needle and flame exploration needle simultaneously.

Note: the incinerator has Windows, and the gas controller must determine whether there is a flame. No flame please follow method 1. If there is flame, please follow method 2 to deal with it.