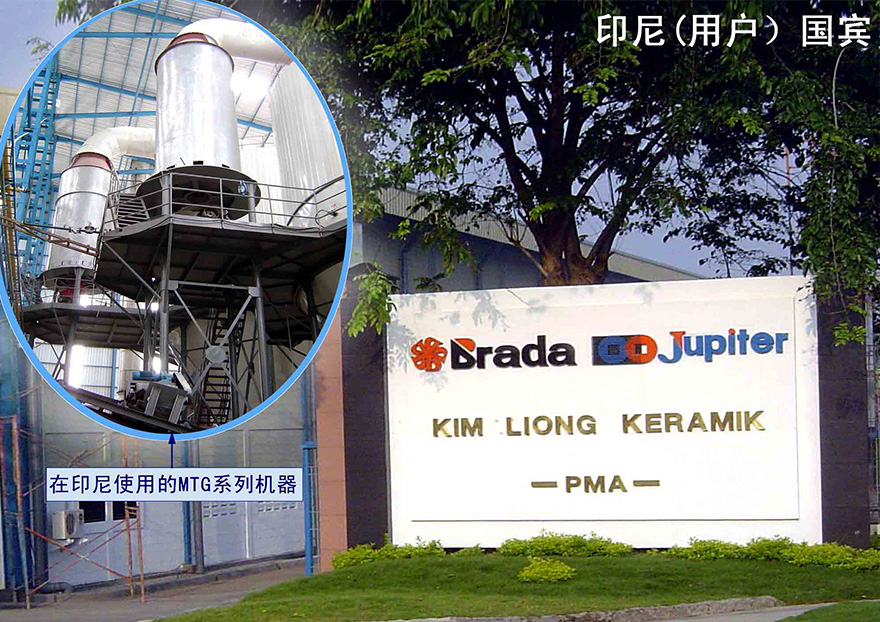

Use and operation of gas steam boilers

2022-05-06 10:42:09

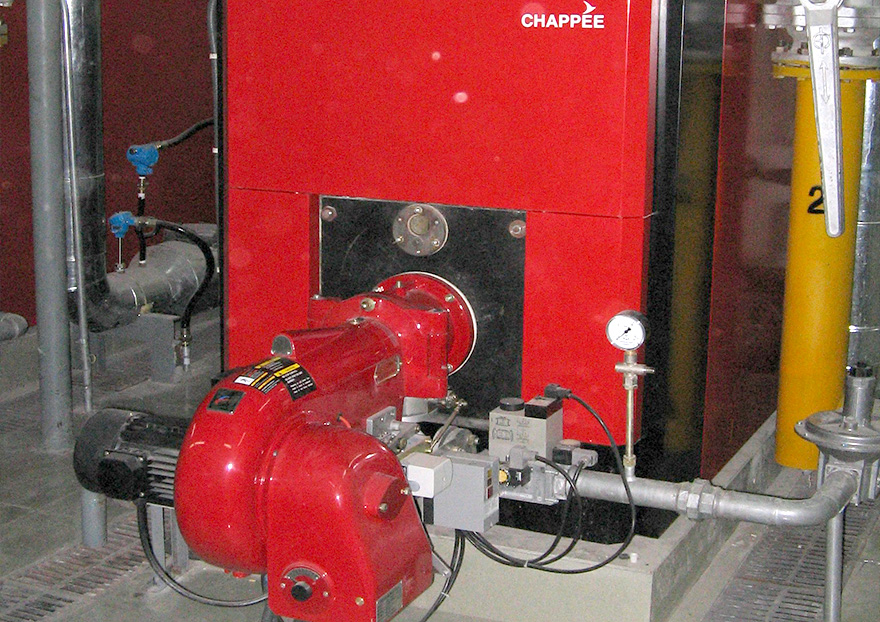

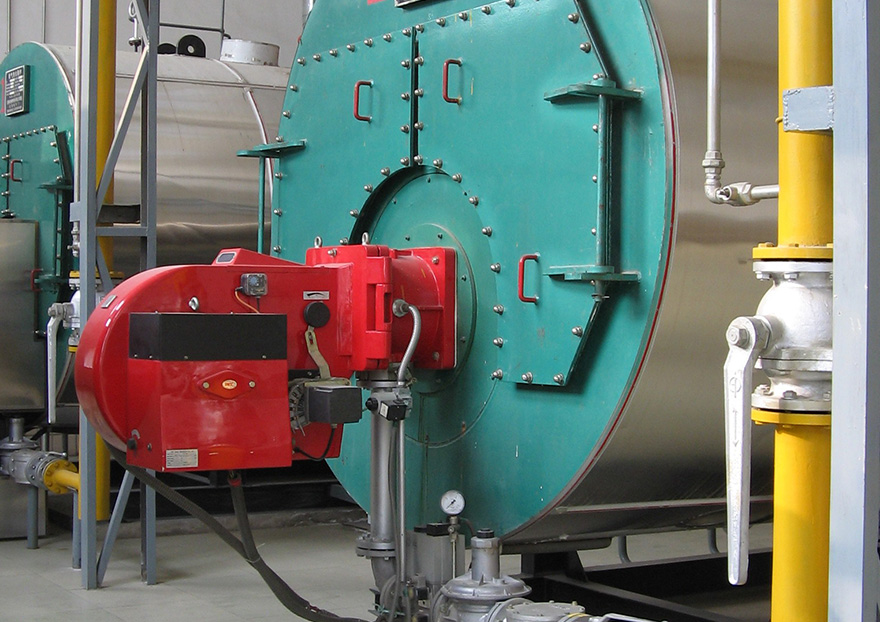

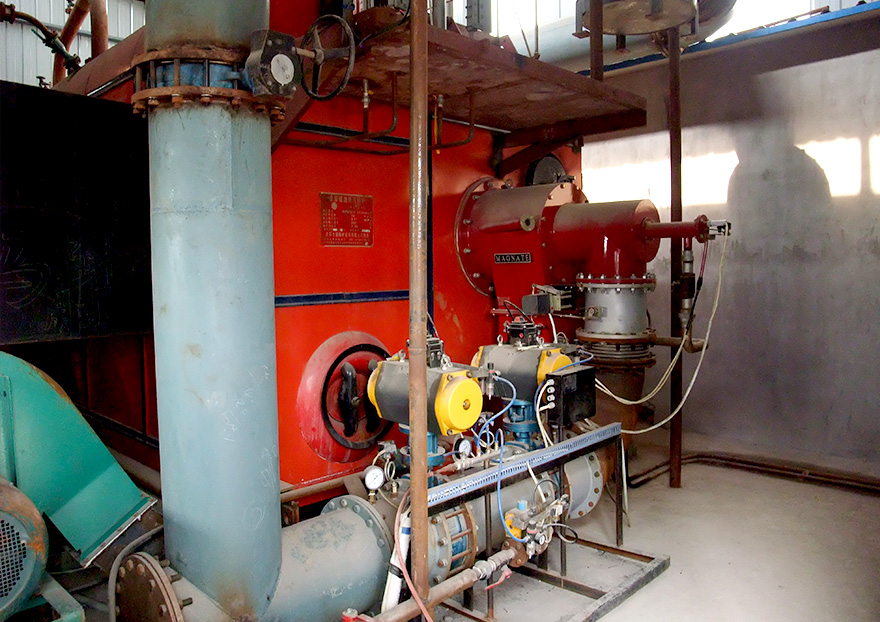

Small natural gas steam boiler refers to the use of small units of natural gas steam boiler, this burner is vertical structure, choose incineration method, two return structure, fuel incineration is abundant, the burner is stable; The spoiler is inserted in the smoke tube to slow down the smoke exhaust speed, add heat exchange, high thermal efficiency of the burner, and reduce the cost of users.

Small natural gas steam boiler furnace selection of vertical tube, four return structure. Useful addition of flue gas to the furnace water large heat transmission, thermal efficiency improvement, good energy saving effect. No tube planning, so that the goods will not be burned due to scaling, heat evenly transmitted to the tube wall and heat transfer fin, prevent stress, prolong the service life. Compared with similar products, it has large incineration chamber, low outlet temperature of furnace liner, threaded smoke pipe as the primary convection heating surface, upper smoke chamber can also be equipped with waste heat recovery heat exchanger, which can greatly save energy.

◇ The products are subject to the supervision and inspection of the burner pressure vessel inspection institute. The planning, materials and production process completely conform to the national existing burner production standards, quality assurance, safety and reliability.

Control system planning leading, reasonable; Water supply, incineration, incineration, fault maintenance and other chain control, complete fuel burning, high thermal efficiency, no black smoke, no environmental pollution.

◇ The primary electrical control selection of famous brand goods, reliable function, low fault rate, high equipment use rate.

One machine multi-purpose; It can supply steam for ironing, other clothing making equipment and other air supply equipment.

◇ High quality steam, low water content, sufficient evaporation, stable pressure.

Beautiful appearance, reasonable price, simple equipment, convenient use, low operating cost.

Widely used in garment, wool weaving, ironing, steam sauna, small food, chemical and other professional steam source.

Burner burner is supplied by a famous manufacturer. In accordance with the command of the controller, the burner is actively burned and suspended. The independent program controller has a number of safety maintenance, safe and stable function, and low repair rate. 2, the leading steam burner full active controller, full Chinese LCD screen, man-machine interface, users only need to easily set, the burner can start and stop according to the user request, load conditioning, active water supply and other full active operation. The burner has complete function, thorough maintenance, simple operation, safe and reliable, and has self-diagnosis function. Once there is abnormal phenomenon in the burner operation, it will actively stop burning and announce sound and light alarm. 3. Vertical steam burner chooses incineration machine lower method, two return structure, fuel incineration is abundant, burner operation is stable; The spoiler is inserted in the smoke tube to slow down the smoke exhaust speed, add heat exchange, high thermal efficiency of the burner, and reduce the cost of users. 4, horizontal steam burner for pot shell type full wet back downstream three return fireworks tube structure, the flame in the large incineration room micro positive pressure incineration, completely expanded, incineration heat load is low, high thermal efficiency, useful to reduce the smoke exhaust temperature, energy saving and consumption reduction, the use of economic. The structure of corrugated furnace and threaded smoke tube improves the heat absorption intensity of the burner and satisfies the demand of heat exchange surface being heated and enlarged. It is scientific and reasonable and durable. 5, the burner strictly in accordance with the "steam burner safety supervision regulations", JB/T 10094-2002 "industrial burner general skills conditions", JB/T 1619-2002 "pot shell burner body production skills conditions" request, planning, production, supervision, to ensure the good quality of the burner, Low energy consumption, high thermal efficiency, stable pressure, gas supply, economic use. 6. The burner has large space, more stored steam and strong ability to adapt to load. Reasonable planning of the built-in soda water separator equipment, to meet the requirements of users to use high quality steam. Furnace body with manhole, head hole, hand hole, easy to arrange the furnace liner, so that repair, maintenance is very convenient. 7, the multistage burner safety with interlocking maintenance: maintain pressure switch (higher than the set pressure active stop and alarm), low water level maintenance (burner water level of the body below the warning level, take the initiative to the detection power and alarm), the relief valve maintenance (burner pressure beyond homework, actively discouraged step-down), ensure the burner in various working conditions is quite safe, arrived back home safe and sound. 8, organic combination of mechanical and electrical integration appearance, exquisite novel, compact structure, less space, convenient transportation, equipment. 9, choose new heat insulation material and excellent white color steel plate packaging, weight is light, good heat preservation function, beautiful and generous, not easy to rust. 10, the whole active/gas steam boiler is widely used in hospitals, campus supermarket, textile mills, garment factories, garment, garment factories, dry cleaning shops, restaurants, hotels, shops, hotels, canteens, restaurants, and of steamed buns, beverage factory, soy products, meat products factory, cannery, brewery, pharmaceutical factory, packaging plant, building materials factory, paint factory, beauty salons, bath center, sauna, steam room, Baby swimming pool and other enterprises and institutions.

1. It is necessary for the personnel who operate the burner to be familiar with the function of the burner and the relevant safety knowledge, and to work with the certificate. It is forbidden for non-post personnel to operate. The personnel on duty shall make operation records and transfer records carefully in strict accordance with the provisions, and the transfer shall disclose the safety situation of the equipment and operation. Check if the burner is in good condition when you take over.

2. Burners and safety accessories should be checked and qualified, and within the useful period.

3. Prepare before starting the furnace

The gas furnace to check the gas pressure is normal, not too high or too low, open the oil and gas supply node door; (2) Check whether the water pump is on, or turn open the valve, until the water stop. Turn over each nozzle of the water system (including the nozzle before and after the water pump and the burner); (3) check the water level meter, water level should be in the normal direction, water level meter, water level plug should be in the open position, root off the false water level, if water shortage can be manually water; (4) check the valve on the pressure pipeline, it is necessary to open, the wind baffle on the flue is necessary to open all; ⑤ Check that all the knobs on the control cabinet are in the normal position; Check the steam burner outlet valve should be closed, hot water burner circulating pump outlet valve should also be closed; ⑦ Check the softening water equipment is not normal operation, the production of soft water is not consistent with the national standard.

4. Start the furnace for operation

1) Steam burner (1) Turn over the main power supply; ⑵ Start the burner; (3) When the exhaust valve on the drum is completely steam, it shall be closed; (4) Check the burner manhole, hand hole flange and valve, found leakage to tighten, tighten such as leakage, stop furnace maintenance; ⑸ When the air pressure rises 0.05 ~ 0.1mpa, water supply, sewage, check the experimental water supply system and sewage equipment, and wash the water level meter; ⑹ Pressure rose to 0.1 ~ 0.15mpa, wash the pressure gauge water trap; Pressure increased to 0.3mpa, "load fire/small fire" knob to "fire", strengthen incineration; ⑻ when the air pressure rises to 2/3 of the operation pressure, the beginning of the warm pipe air, slowly open the main steam valve, to prevent water strike; The drainage valve is completely closed when steam is emitted; We will all drainage valve closed, slowly open the main gas valve to fully open, and then reverse half circle; 11 "burner control" knob to "active"; (12) water level conditioning: according to the load conditioning water level (manual start and stop feed pump), low load water level should be slightly higher than the normal water level, high load, water level should be slightly lower than the normal water level; (13) How to adjust the smoke setting temperature (14) According to the loading conditioning incineration (manual conditioning large fire/small fire), (14) according to the flame color, smoke color, air quantity (14) fuel atomization (spends) (15) investigating the smoke exhaust temperature, the smoke temperature is generally controlled between 220 and 250℃, and the smoke exhaust temperature and concentration of the chimney are investigated, and the incineration is adjusted to the operation condition. 2) Hot water burner (1) Turn over the total power supply; Start the circulating pump; (3) slowly open the circulation pump outlet valve; (4) Start burner; ⑸15 minutes later, "Load fire/small fire" color button to "fire" "burner control" knob to "active". 5. Normal shutdown: hot water burner A normal shutdown: hot water burner ① "load fire/small fire" knob to "small fire"; ② Closed burner; Close the fuel supply valve; After the water temperature of the burner drops to 50℃, the outlet valve of the circulating pump is closed. ⑥ Stop circulating pump steam burner (1) "load fire/small fire" orientation; ② Closed burner; (3) discharge when the steam pressure drops to 0.05-0.1mpa; (4) close the main steam valve; ⑤ Manually refill water to slightly higher water level; ⑥ Close the water supply valve; Closed incineration supply valve; ⑧ closed flue baffle; ⑨ Close the main power supply B urgent stop hot water burner ① Close the inlet and outlet valves of the burner; (2) Open the urgent discharge valve and urgent water refill valve; (3) close the total power switch; Tell the superior leadership; Steam burner (1) close the main steam valve; ② Closed total power supply; ③ Tell your superiors.